Description

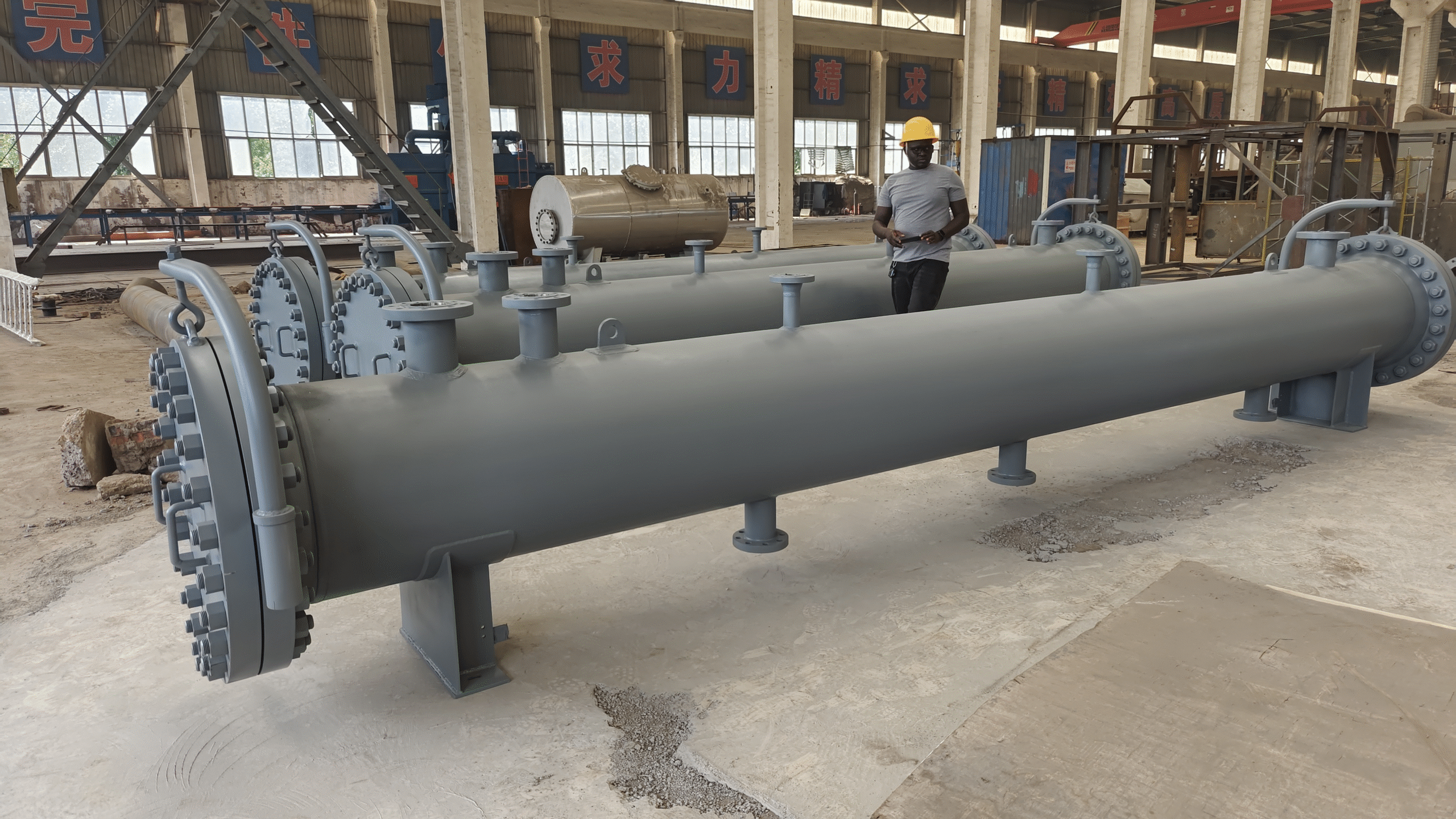

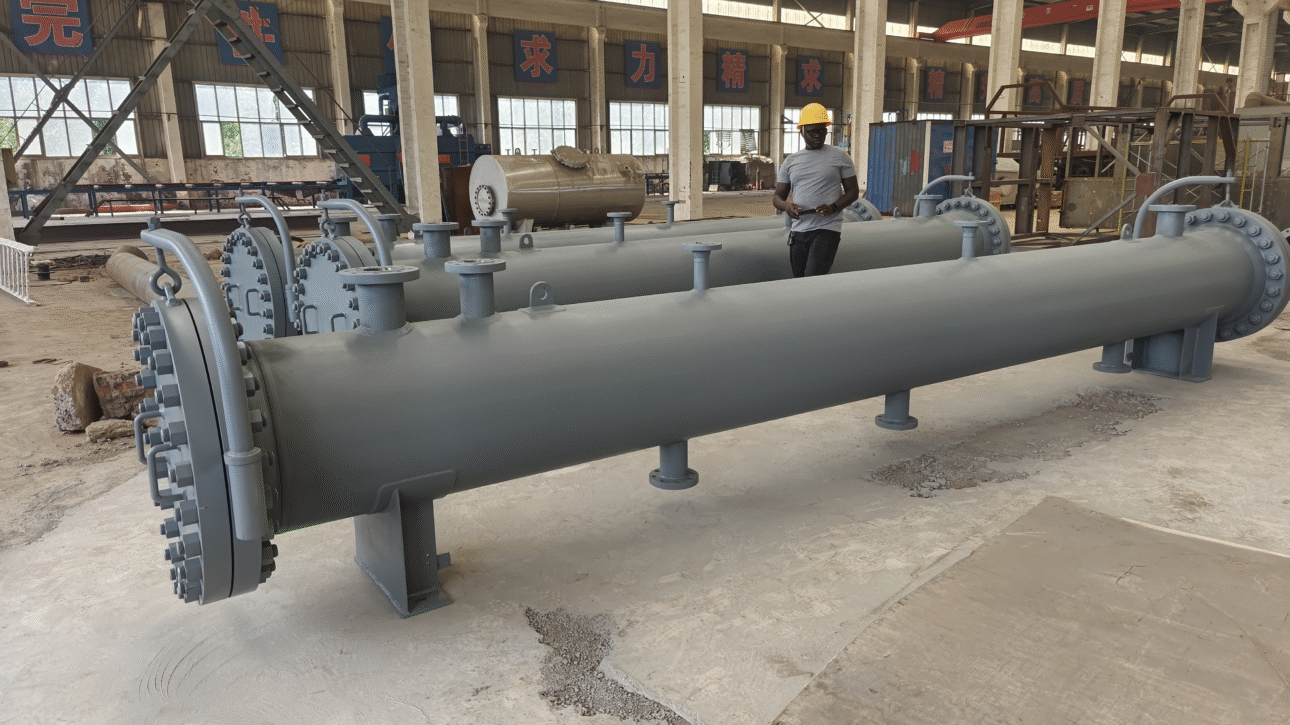

Pig Launcher and Receiver is a critical tool in the pipeline industry, playing a vital role in maintaining pipeline efficiency and integrity. These devices facilitate the insertion and retrieval of pipeline inspection gauges, commonly known as pigs. Pigs perform various functions such as cleaning, inspecting, and separating different batches of product within the pipeline.

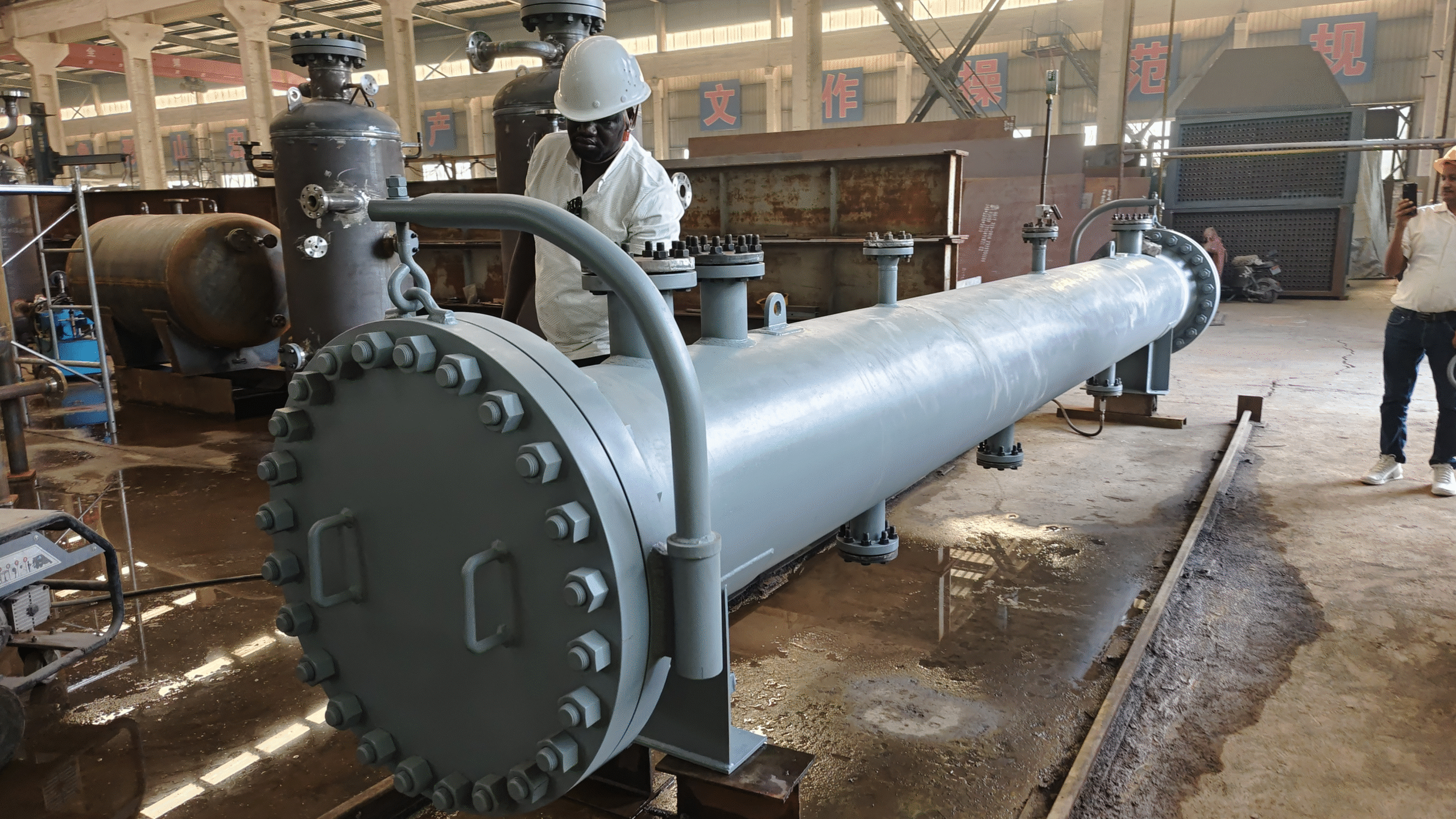

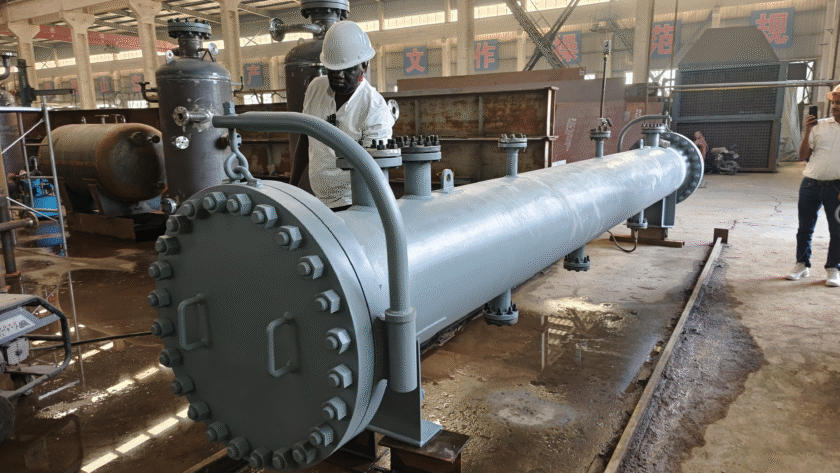

Starting with the pig launcher, it is essentially a device that introduces the pig into the pipeline. Typically located at the beginning of the pipeline or at strategic points along the pipeline, the launcher consists of a Y-shaped section of pipe. Operators load the pig into the launcher’s chamber, which is sealed with a closure. Once the launcher is pressurized to match the pipeline’s pressure, the pig is forced into the pipeline.

The Using Process of Pig Launcher and Receiver

The process is controlled using valves that regulate the flow and pressure within the launcher. This setup ensures that the pig enters the pipeline smoothly and begins its journey. The operation requires careful coordination to synchronize with the product flow in the pipeline, minimizing disruption and maintaining pressure stability.

Transitioning to the pig receiver, this device safely removes the pig from the pipeline at journey’s end. It is located at the pipeline’s opposite end or at a designated receiving point. The receiver features a Y-shaped section similar to the launcher. It includes a chamber with a closure that can be safely opened. Operators can retrieve the pig from this chamber once it completes its task.

The receiver also has a series of valves that control the decompression and isolation of the pig from the main pipeline. This allows for the safe extraction of the pig, ensuring that both the pig and the pipeline are not damaged during the process. The receiver must handle the pig gently to preserve its integrity for future use.

Features of Pig Launcher and Receiver

Moreover, Pig Launcher and Receiver features designs that accommodate different types of pigs and pipeline configurations for versatility. Manufacturers build them to withstand the harsh conditions common in pipeline environments, such as high pressures and corrosive materials. Their robust construction ensures long-term reliability and functionality.

Additionally, the design of pig launchers and receivers includes safety features to protect operators and the environment. These features include pressure relief valves, burst discs, and emergency shutdown systems that activate in the event of a malfunction. Such safety mechanisms are crucial for preventing accidents and mitigating potential hazards associated with pipeline operations.

Operationally, pig launchers and receivers contribute significantly to pipeline maintenance. By facilitating regular pigging operations, they help prevent the buildup of deposits and blockages that can reduce the pipeline’s efficiency or lead to corrosion. Regular use of pigs enhances the pipeline’s operational life and reduces the need for costly repairs or replacements.

Conclusion

In conclusion, Pig Launcher and Receiver is an indispensable tool in the pipeline industry. They provide a mechanism for the safe, efficient, and effective management of pipeline inspection and maintenance operations. Their robust design and safety features ensure that they can meet the demands of various pipeline environments. Consequently, they play a crucial role in maintaining the smooth operation of pipelines, ensuring the integrity and longevity of one of the industry’s most vital assets.

Pig Launcher and Receiver systems are vital in the pipeline industry. They facilitate the safe, efficient, and effective management of pipeline inspection and maintenance. With robust designs and integrated safety features, these systems reliably meet diverse environmental demands. As a result, they are essential for ensuring smooth pipeline operations, protecting the integrity and extending the longevity of critical infrastructure. Their ability to prevent buildup and corrosion translates directly into fewer breakdowns and reduced downtime, optimizing operational continuity and safeguarding the industry’s essential assets.