Description

A Pig Passage Indicator is a crucial tool used in pipeline maintenance to detect the passage of a pig (pipeline inspection gauge) through a specific point in a pipeline system. This device enhances the safety and efficiency of pigging operations by providing immediate feedback to operators. Here, we’ll explore how a Pig Passage Indicator works and its benefits in pipeline maintenance.

How a Pig Passage Indicator Works

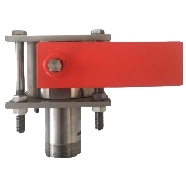

Detection Mechanism: The PPI typically includes a mechanical, magnetic, or electronic sensor that detects the pig as it passes the point where the indicator is installed. Mechanical indicators may use a flag or wheel that pops up when triggered, while magnetic and electronic types can activate an alert system.

Installation: Operators install Pig Passage Indicators at strategic points along the pipeline, especially at critical bends, junctions, and ends. Proper installation ensures accurate detection and signaling.

Operation: As the pig moves through the pipeline, it activates the indicator when it passes by. This activation can trigger a visual signal, such as a flag, or send an electronic signal to a remote monitoring station.

Benefits of Using aPig Passage Indicator

Pig Passage Indicators are crucial for real-time monitoring of pigging operations. They ensure pigs move smoothly without stalls or losses. This enhanced monitoring is vital for maintaining operational safety. The indicators confirm the passage of pigs through critical pipeline points, preventing accidents from unexpected stops or collisions. Moreover, their accurate tracking allows operators to optimize pigging schedules. This optimization effectively reduces downtime and boosts maintenance efficiency.

The cost-effectiveness of PPIs arises from their ability to reduce manual checks. They also lower the risk of pipeline damage or the need for reactive maintenance, significantly cutting costs. These indicators are versatile enough for various pig types, including cleaning, gauging, and inspection pigs. They adapt well to different pipeline environments and materials. Additionally, most Pig Passage Indicators are easy to install and maintain. They require minimal technical skills and do not disrupt normal pipeline operations, making them a valuable part of pipeline management systems.

Parameters

| Type: Intrusive |

| Connection type: Flange connection |

| Indicator feature: Manual reset flag combined with electrical signals (Manual reset flag and Date and time display combined with electrical signals can also be made) |

| Installing type: 2” Flange. As per ASME B16.5(CLASS150-2500) |

| Plug body length: 200mm/Meet the actual needs |

| Insert depth adjustment: 20mm |

| Operating temperature: -20~120℃/Meet customer requirements |

| NACE MR 0175: Yes |

| Ingress protection: IP66 |

| Explosion-proof class: Exd II BT4 |

| Remove under pressure: No |

| Trigger type: Bi-directional (Uni-directional trigger can also be made) |

| Internal part material: PTFE Coated A105N is standard configuration (304SS/316LSS/DSS/INCONEL/As per MR can meet customer needs) |

| Junction box material: Aluminium alloy/316SS |

| Switch type: DPDT/2*SPDT |

| Switch rating: DC24V 3A/DC24V 5A |

Features of Pig Passage Indicator

Pig Passage Indicators are essential tools in the pipeline industry that use mechanical, magnetic, or electronic sensors to detect the passage of a pig. They offer visual, audible, or electronic signals to indicate when a pig passes a specific point in the pipeline. These devices are versatile, accommodating various types of pigs such as foam, cleaning, gauging, and smart pigs. Pig Passage Indicators are durable enough to withstand harsh environments, extreme pressures, and temperatures, ensuring reliable performance. They are easy to install and maintain, which is vital for pipelines that stretch across large distances or remote areas.

The pig indicator works with different pipeline materials and diameters, making them a flexible option for many systems. By providing real-time, accurate detection of pig locations, Pig Passage Indicators enhance operational safety by helping to prevent pipeline damage and pigging accidents. They also reduce the need for manual inspections and potential reactive maintenance, significantly cutting operational costs and improving the efficiency of pipeline maintenance programs. Overall, Pig Passage Indicators play a crucial role in maintaining the integrity and efficiency of pipeline operations.

Different Types

| Indicator Types | ||||

| Indicator Types | A | B | C | D |

| Intrusive Type | Intrusive | Intrusive | Intrusive | Non-intrusive |

| Indicator Features | Popper Type | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals |

Intrusive Type

Intrusive PPIs physically penetrate the pipeline to directly detect the passage of a pig. They often use mechanical methods, such as a probe extending into the pipeline. This probe is triggered by the pig’s movement. Direct contact with the pig provides highly accurate detection. Intrusive PPIs are commonly used in smaller or less complex pipeline configurations. However, their intrusive nature makes them susceptible to wear and tear. They may require more frequent maintenance.

Non-Intrusive Type

Non-intrusive PPIs do not penetrate the pipeline wall; instead, they detect pigs through the pipeline material using methods such as magnetic, ultrasonic, or acoustic sensors. These indicators are mounted on the outside of the pipeline and can detect the pig as it passes by sensing changes in magnetic fields, sound, or other properties. Non-intrusive PPIs are ideal for larger pipelines or those handling corrosive or hazardous materials, as they do not compromise the integrity of the pipeline. They are generally easier to install and maintain, offering a safer and more durable option for challenging environments.

Both types of PPIs fulfill essential roles in pipeline management, ensuring safe and efficient pigging operations tailored to different operational requirements and environmental conditions.