Description

Introduction To Pig Signal Indicator

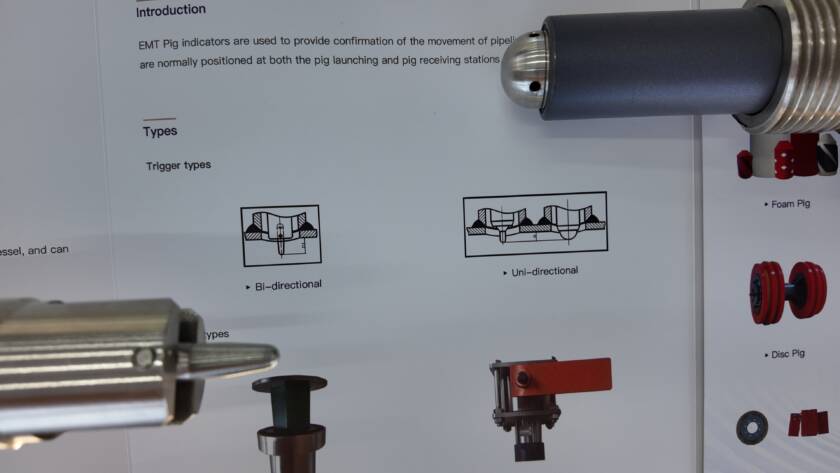

A Pig Signal Indicator is a specialized device that pipeline operators use to detect the presence and passage of a “pig” — a tool sent through pipelines for cleaning or inspection purposes. Operators install these indicators at specific points along the pipeline to provide immediate feedback when a pig passes a certain location. This feedback can be visual, mechanical, or electronic, depending on the design of the indicator.

Pig Signal Indicators are essential for ensuring the efficient operation of pigging activities, as they confirm that the pig has traveled the intended path without becoming stuck or lost. They are particularly crucial in long or complex pipeline systems where visual confirmation is not possible. By providing real-time data on the pig’s location, these indicators help maintain the flow and integrity of the pipeline, ensuring that maintenance and inspection tasks are completed successfully and on schedule.

Parameters

| Name | Removable Pig Indicator with an Isolation Valve |

| Connection | Welded Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01-75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | Yes |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

| Specification | |

| Type | Intrusive |

| Connection Type | Flange connection |

| Indicator Feature | Manual reset flag; Date and time display combined with electrical signals (optional) |

| Installing Type | 2″ Flange, ASME B16.5 (CLASS 150-2500) |

| Plug Body Length | 200 mm or as per actual needs |

| Insert Depth Adjustment | 20 mm |

| Operating Temperature | -20 to 120°C or as per customer requirements |

| NACE | MR 0175 |

| Ingress Protection | IP66 |

| Explosion-Proof Class | Exd II BT4 |

| Remove Under Pressure | No |

| Trigger Type | Bi-directional (Uni-directional trigger also available) |

| Internal Part Material | PTFE Coated A105N (Options: 304SS, 316LSS, DSS, INCONEL, or as per MR) |

| Junction Box Material | Aluminium alloy or 316SS |

| Switch Type | DPDT or 2*SPDT |

| Switch Rating | DC24V 3A or DC24V 5A |

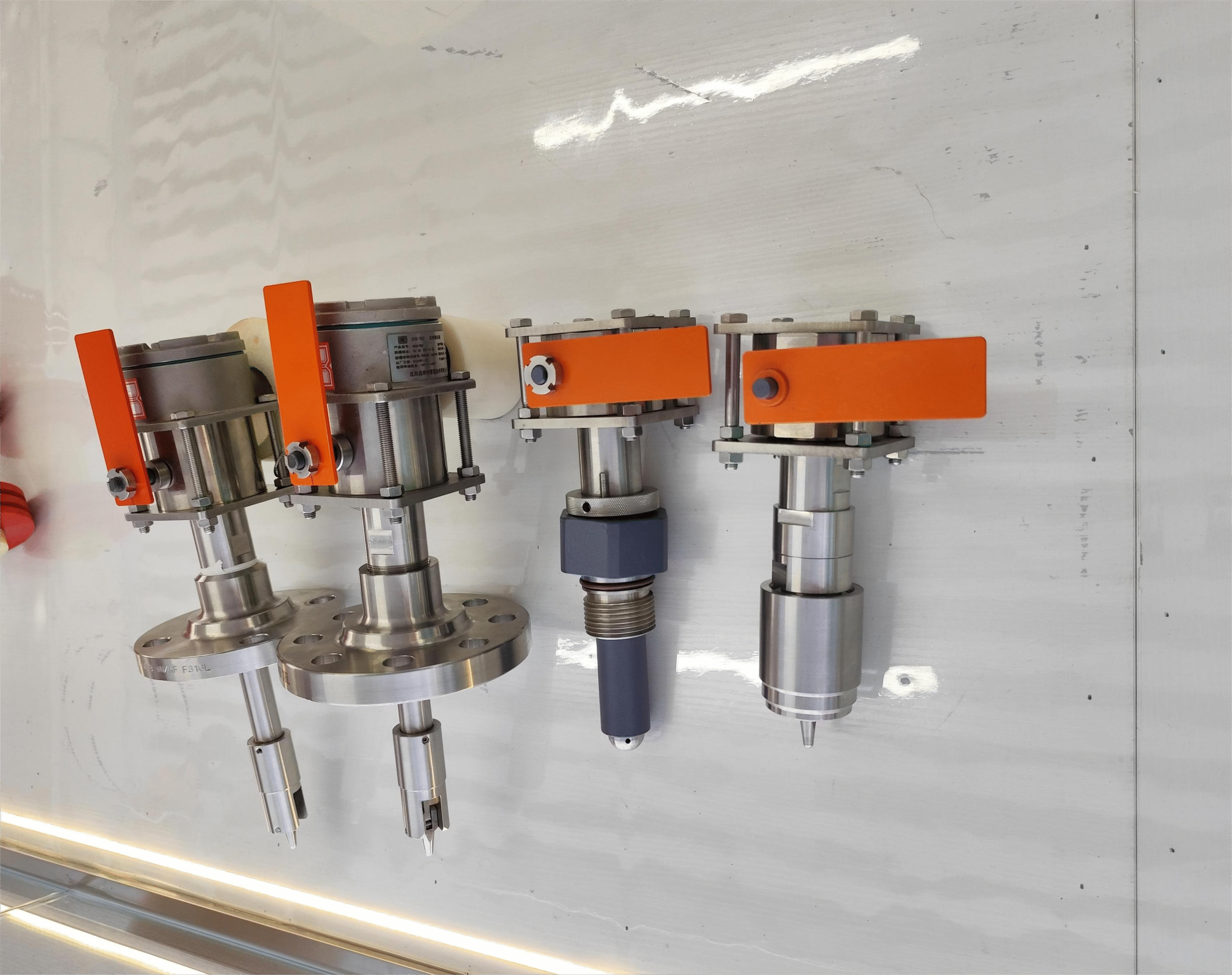

Different Types of the Pig signalers

Types of Pig Signal Indicators include both Mechanical and Non-Intrusive Pig Signals, each catering to specific operational needs.

A. Mechanical Pig Signals

Mechanical pig signals are a traditional choice in pipeline operations. These devices operate through a direct mechanical action. When a pig passes, it triggers a flag or wheel. This mechanism provides operators with clear visual confirmation of the pig’s passage. Most operators favor mechanical signals for their simplicity and reliability. The straightforward design of these indicators makes them easy to use and understand. They require direct contact with the pig, ensuring accurate detection each time. Due to their robust nature, these signals perform well in various conditions without the need for complex technology.

B. Non-Intrusive Pig Signals

On the other hand, non-intrusive pig signals offer a modern detection solution. These indicators detect pigs without making physical contact. They utilize technologies such as magnetic, ultrasonic, or acoustic sensors. By doing so, they avoid any disruption to the pipeline’s integrity. This method significantly reduces the risk of mechanical failures. Non-intrusive signals are particularly beneficial for pipelines transporting sensitive or hazardous materials. They also support remote monitoring capabilities. This feature greatly enhances operational safety and efficiency. Operators can monitor the pig’s progress from a distance, adding an extra layer of convenience and safety.

Applications of Pig Signal Indicator

Pig Signal Indicators serve multiple applications across various industries, enhancing both safety and efficiency in pipeline maintenance and operations.

In the oil and gas industry, operators use Pig Signal Indicators to ensure the cleaning or inspection pigs have successfully passed through critical sections of a pipeline. This is crucial for preventing blockages and maintaining smooth operational flow. Additionally, these indicators help in the timely detection of possible deposits or anomalies inside the pipeline, which could lead to significant operational disruptions if left unchecked.

Furthermore, in chemical manufacturing, maintaining purity and preventing contamination are paramount. Here, Pig Signal Indicators allow for the safe and efficient transportation of chemicals through pipelines. They ensure that cleaning processes have been completed thoroughly before a new product batch is processed. This prevents cross-contamination and ensures product quality.

In the water treatment sector, Pig Signal Indicators play a vital role in managing pipeline cleaning schedules. They confirm the completion of pigging operations, which are essential for removing sediment and other deposits from water transport pipelines. Ensuring these pipelines are clean avoids potential health hazards and maintains the efficiency of water flow.

Moreover, Pig Signal Indicators also find applications in the food and beverage industry. They ensure that pipelines used for transporting liquid ingredients or finished products are free from contaminants. This is essential for complying with strict hygiene standards and ensuring consumer safety.

In the utility sector, Pig Signal Indicators aid in the maintenance of sewage and drainage systems. They help ensure that inspection or cleaning pigs have traversed the system as planned, preventing untreated waste from causing environmental damage.