Description

Mechanical Type Pig Signaler Technical Properties

The Mechanical Type Pig Signaler is designed for use in demanding pipeline applications and offers a robust set of technical properties. It operates effectively within a pressure range of ≤35 MPa and a temperature range of -40℃ to 100℃, making it suitable for harsh environments. The device supports pipeline diameters of DN100 and above, and it accommodates petroleum products, natural gas, and other non-corrosive liquids. The input needle extends 46 mm into the pipeline, ensuring accurate detection of pig passage. Under standard conditions, the recommended installation height is 1.1 meters.

Engineers can safely install this pig signaller in explosion-proof environments, as it meets the requirements for hazardous areas classified as Zone 1 and Zone 2. It carries an explosion-proof rating of dⅡBT4, a protection grade of IP65. These features make the pig signaller an ideal choice for operations in oil and gas pipelines, ensuring both safety and reliable performance in potentially hazardous conditions.

Display Method

The display method involves a site-indicating flag with manual replacement, operating at a capacity of 24VDC and 2A.

Equipment structure

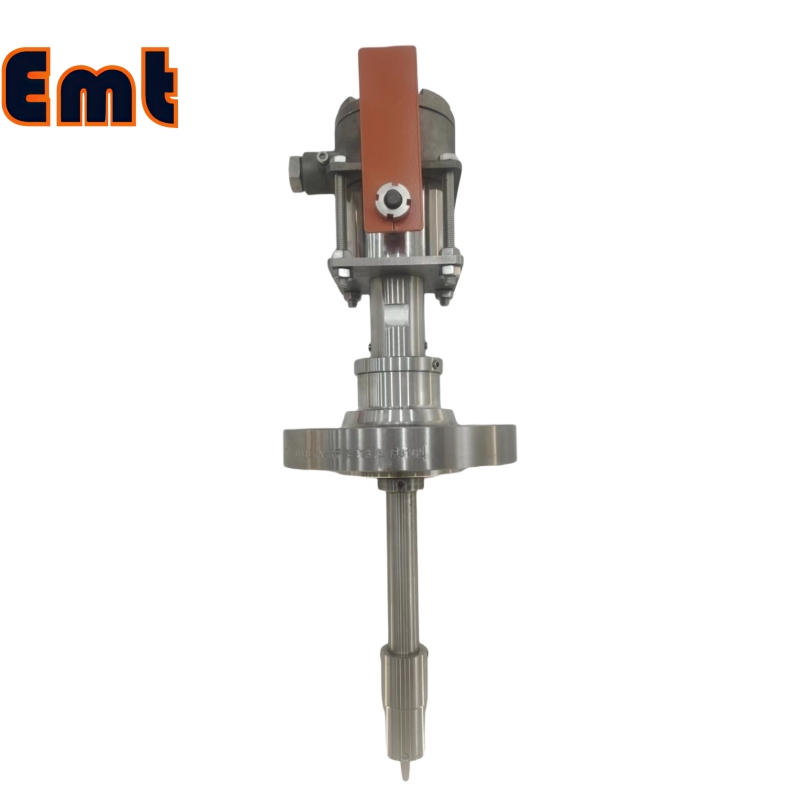

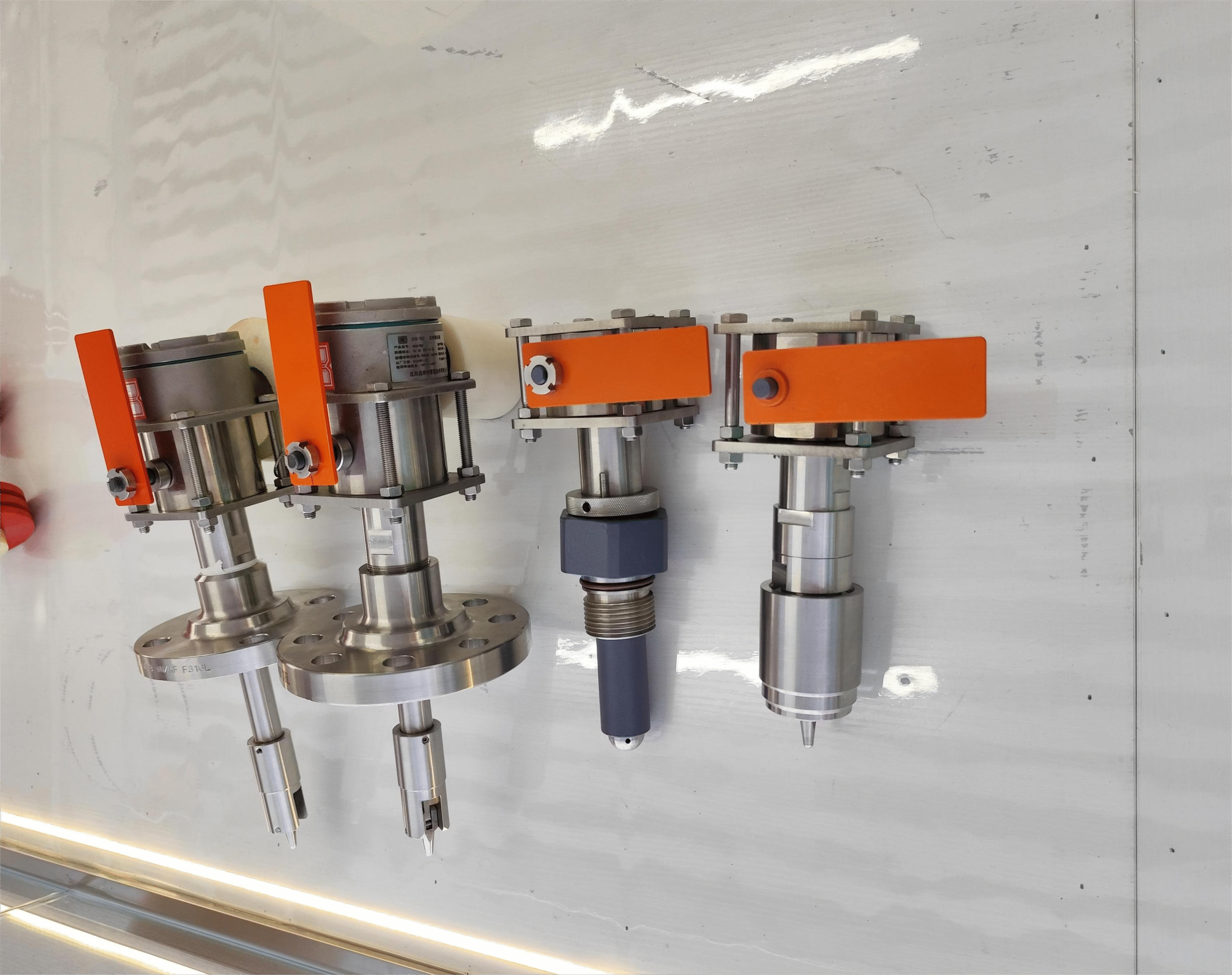

The system consists of several interconnected components designed for safe disassembly under pressure. The basement is welded directly to the pipeline, providing a stable foundation. A mounted flange, made of stainless steel, connects the ball valve to the basement. The stainless steel ball valve serves as the primary component for enabling disassembly under pressure. The mechanical body, also stainless steel, is the main part facilitating this function. A vent inlet, made of stainless steel as well, allows for secondary pressure release. A locating bolt ensures proper alignment and positioning, while an adapter ring connects the mechanical body to the clock head. Finally, a safety pallet provides a self-locking safety feature to enhance operational security.

Specifications

| Specification | |

| Type | Intrusive |

| Connection Type | Flange connection |

| Indicator Feature | Manual reset flag; Date and time display combined with electrical signals (optional) |

| Installing Type | 2″ Flange, ASME B16.5 (CLASS 150-2500) |

| Plug Body Length | 200 mm or as per actual needs |

| Insert Depth Adjustment | 20 mm |

| Operating Temperature | -20 to 120°C or as per customer requirements |

| NACE | MR 0175 |

| Ingress Protection | IP66 |

| Explosion-Proof Class | Exd II BT4 |

| Remove Under Pressure | No |

| Trigger Type | Bi-directional (Uni-directional trigger also available) |

| Internal Part Material | PTFE Coated A105N (Options: 304SS, 316LSS, DSS, INCONEL, or as per MR) |

| Junction Box Material | Aluminium alloy or 316SS |

| Switch Type | DPDT or 2*SPDT |

| Switch Rating | DC24V 3A or DC24V 5A |