Description

For quick and reliable corrosion rate measurements in water systems, choose the EMT Portable LPR Corrosion Rate Instrument. This user-friendly, handheld device connects directly to an LPR probe—simply plug it in and press the measure button. Within minutes, it displays key data including corrosion rate in mils per year (MPY), electrode imbalance, conductivity, and, when used with an ER Temperature LPR probe, water temperature. Featuring patented Solution Resistance Compensation, the EMT instrument operates effectively across a wide conductivity range—from cooling water to condensate, feedwater, and even drinking water—without the need for manual conductivity adjustment. With a pre-programmed alloy multiplier, it delivers accurate corrosion rates effortlessly. It also measures electrode imbalance current, offering insight into potential pitting activity. Compact enough to fit in a shirt pocket and powered by a single 9-volt battery, the EMT LPR sets a new benchmark for portable corrosion monitoring technology.

Overview

The Portable LPR Corrosion Rate Instrument is a compact, field-ready device designed to measure corrosion rates quickly and accurately. It uses Linear Polarization Resistance (LPR) technology, which is a proven method for detecting corrosion activity in metals. This technique involves applying a small electrical signal to a metal surface and analyzing the voltage response to determine the corrosion rate. Technicians rely on this instrument in industries like oil and gas, water treatment, and chemical processing, where corrosion monitoring is critical.

Features

The instrument offers a range of valuable features for efficient corrosion monitoring. It provides accurate corrosion rate measurements and detects imbalance currents, which can indicate pitting activity. Users can easily select alloy multipliers to match different materials, ensuring precise readings. Designed for simple, intuitive operation, the device is also CE compliant, meeting essential safety and performance standards.

Design and Portability

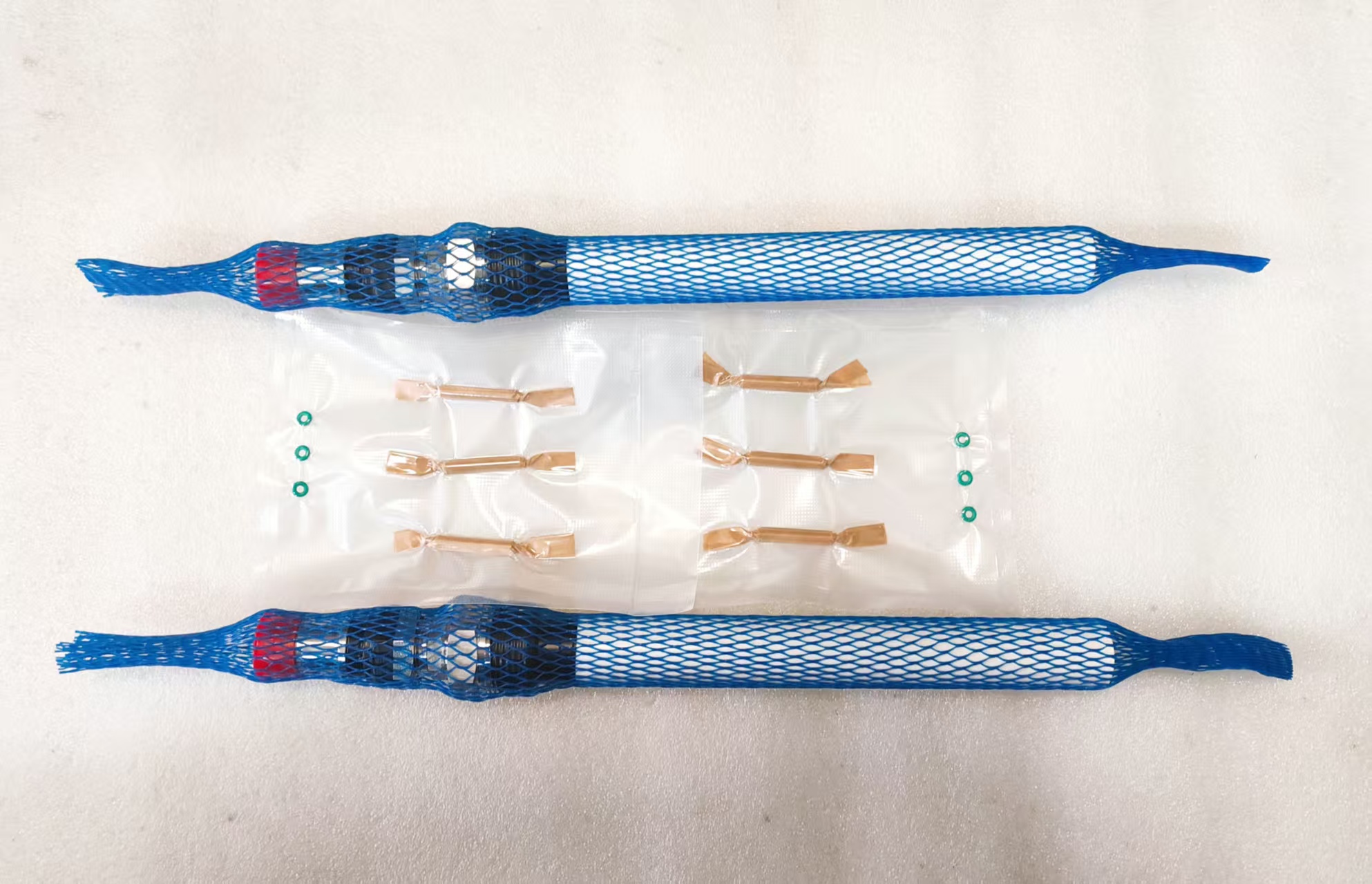

The device is highly portable, allowing users to carry it easily to remote or difficult-to-access locations. Its lightweight and rugged design ensures it performs reliably even in harsh environments. The instrument typically includes a handheld unit with a digital display, a sensor probe, and connection cables. Users simply connect the probe to the metal surface, start the reading, and receive real-time corrosion data within moments. This fast and efficient process helps teams identify problem areas before serious damage occurs.

Ease of Use

In addition, the user interface is simple and intuitive. Operators can navigate the menu, initiate tests, and store results with minimal training. The device often supports multiple sensor types, allowing for flexibility across different applications. Sensor replacement is quick and easy, which minimizes downtime during fieldwork. The instrument can also store multiple data points, enabling users to analyze trends over time and make informed decisions about maintenance planning.

Non-Destructive Testing

Another key advantage is its ability to deliver non-destructive testing results. Since the LPR method does not harm the metal being tested, users can conduct frequent inspections without damaging equipment. This feature is especially valuable for monitoring critical infrastructure like pipelines, storage tanks, and structural supports. By detecting corrosion early, engineers can schedule repairs proactively and extend the lifespan of assets.

Cost Efficiency and Benefits

Moreover, the instrument helps reduce costs associated with unexpected failures, production downtime, and emergency repairs. It supports preventive maintenance strategies and improves overall safety in industrial operations. Some models also offer data export features, allowing users to transfer results to computers for further analysis and reporting.

Conclusion

In conclusion, the Portable LPR Corrosion Rate Instrument is an essential tool for professionals who need reliable, on-the-spot corrosion measurements. It combines accuracy, portability, and ease of use, making it ideal for routine inspections and long-term corrosion monitoring. By using this instrument, industries can protect valuable infrastructure, optimize maintenance schedules, and ensure operational safety.