Description

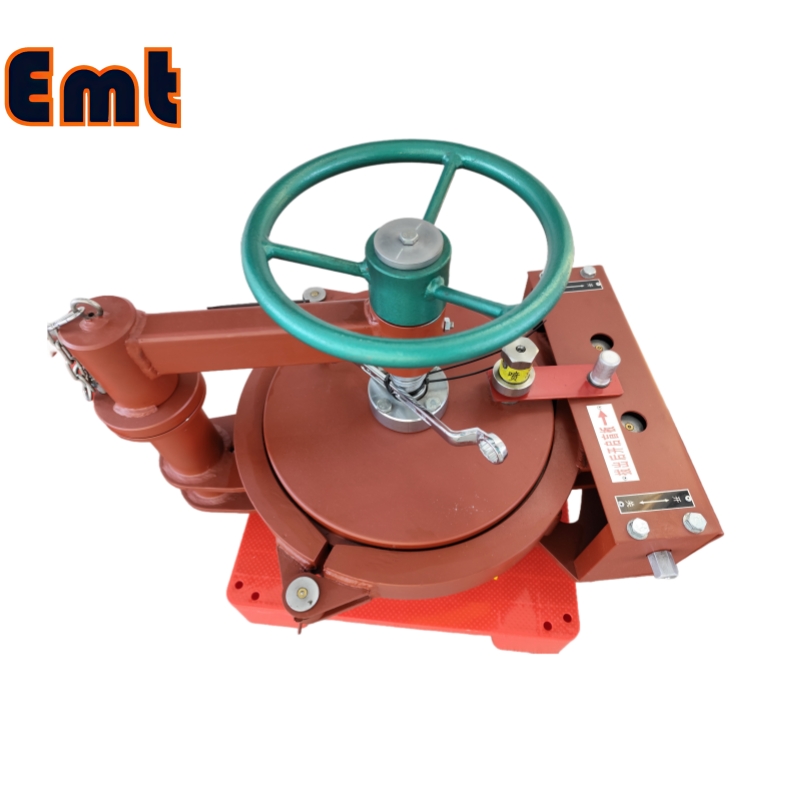

The triple yoke clamp type quick opening closure (QOC) features a large occlusal area, offering high safety and reliability. It is simple to operate and particularly well-suited for use with high-pressure, large-diameter equipment. A safety interlocking mechanism enhances its safety and reliability.

The product consists primarily of an end closure, barrel flange, triple yoke clamp, safety interlocking mechanism, arm mechanism, and an opening and closing mechanism. By using a special wrench to turn one end of the switch screw either clockwise or counterclockwise, you can open or contract the triple yoke clamp. This allows for rapid opening and closing of the mechanism.

This type of quick opening closure (QOC) is widely used in natural gas pipeline, chemical industry, medicine, metallurgy and other fields, such as receiving and sending ball cylinder, tank, pressurized kettle, filtration separator, heat exchanger and other containers and equipment that need to be opened and closed from time to time.

Install of QOC

Initial installation

Quick opening closure initial installation, need to meet the following requirements:

The inner diameter of the quick opening closure should be consistent with the inner diameter of the equipment, the weld counter gap should be uniform, the difference between the maximum and minimum counter gap ≤ 1.0 mm, the amount of misalignment of the counter should be consistent with the provisions of GB 150.4-2011 standards in Table 1;

Before the quick opening closure and the equipment barrel flange are grouped, the welding type should be determined:

a. If double-sided welding is used, the end closure needs to be removed (specific operation according to the manual 2.2 Removal of end closure);

b. If single-sided welding is used, just take down the sealing ring, no need to dismantle the end closure.

Welding and post-welding heat treatment of QOC

Welding and post-welding heat treatment of QOC

Remove the End Closure

When the assembly and maintenance of the quick opening closure requires disassembly of the end closure, follow the steps below:

Place the quick opening closure in a suitable position and open the end closure. Remove the swivel arm shaft top covert as shown in Fig. 1, loosen the adjust bolt, (4 pieces for each top and bottom, 8 pieces in total), and remove the swivel arm Avoid damage to t he threaded portion of the swivel arm shaft by bumping during removal.

Remove the end closure and place it properly.

Welding and post-welding heat treatment

Due to welding stress during the welding process and improper welding operation, etc., may lead to welding deformation, in order to prevent and minimize welding deformation,quick opening closure and equipment barrel flange pairing and welding, should comply with the following provisions:

Counter gap should be uniform, the difference between the maximum and minimum counter gap ≤ 0 mm, the amount of counter misalignment should be in accordance with the GB 150. 4-2011 standard in Table 1;

Before welding, preheat the bevel or follow the provisions of the welding process. During welding, use a small diameter electrode, small current, and the symmetrical, multi-layer welding method to control deformation. Failure to do so may prevent the end closure from opening and closing and could even result in scrapping the quick opening closure!

Post-weld heat treatment recommendations:

Apply local heat treatment to the annular weld between the quick opening closure and the equipment barrel flange. If overall heat treatment is required by manufacturing specifications, protect the sealing surface. Use rock wool, aluminum silicate, or other insulating materials to prevent oxidation. Carry out the heat treatment process strictly according to clause 2 of GB 150.4 or ASME standards. Alternatively, follow the matured heat treatment process of the heat treatment manufacturer.

Please note:

a. Install the end closure after the heat treatment if you removed it beforehand.

b. Remove all seals if you did not take off the end closure before heat treatment.

c. After heat treatment, lightly wipe the sealing surfaces with a fine emery cloth. Then, evenly coat them with grease, glycerin, or antirust oil.