Description

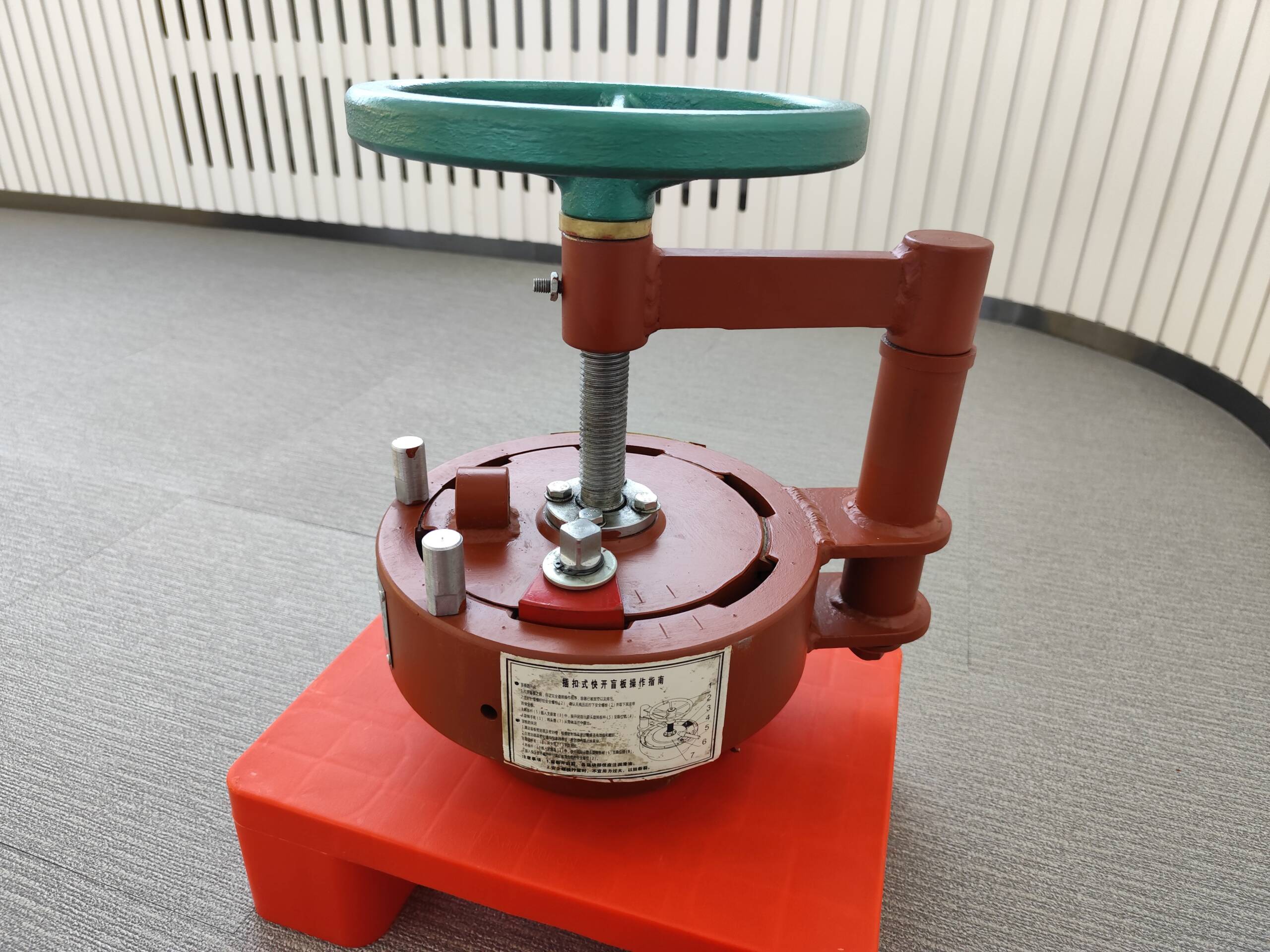

EMT Quick Closures are engineered for high-pressure pipeline applications, specifically designed to facilitate efficient and safe access to pig launchers and receivers. These closures incorporate several advanced features that enhance their performance and reliability.

| Lock Ring Type | Band Type | Plug Buckle Type | |

| Installation | Vertical/Horizontal | Vertical/Horizontal | Vertical |

| Size | DN 200 to DN 1200 | DN 150 to DN 1000 | DN 150 to DN 1000 |

| Pressure | ASME #150 to #1500 | ASME #150 & #300 | ASME #150 to #600 |

| Materials | SA 350 LF2 | SA 350 LF2 | SA 516 70N/SA 105N |

| Sealing | Viton™ | Viton™ | Viton™ |

1. Key Production Features of Quick Closures

- Short Operating Time: The EMT Quick Closure utilizes an innovative locking-ring quick opening mechanism with an integral scalable locking ring structure. This design significantly reduces the time required for opening and closing compared to other types of quick closures. A single operator can complete the process in under one minute with a force of less than 200N, streamlining operations and enhancing productivity.

- Self-Tightening Lip Seal Structure: The closure features a unique self-tightening lip seal that ensures a secure and reliable seal under varying pressure conditions. This design minimizes the risk of leaks, enhancing safety and performance even in high-pressure environments.

- Safety Lock System with Self-Locking Function: The safety lock system includes a self-locking mechanism that provides critical safety features:

- Pre-Booster Locking: Before pressure is boosted, the fast-opening blind and locking structures can secure the equipment, preventing accidental operation unless the appropriate lock position is reserved.

- Post-Unloading Pressure Relief: Once unloading is complete, the system ensures that the inner pressure is fully relieved before the blind flange cover can be opened. This secondary pressure relief mechanism prevents safety hazards resulting from improper operations.

2. Technical Specifications

- Design Pressure: Rated for pressures between 1.6 MPa and 30 MPa, making it suitable for demanding high-pressure applications.

- Corrosion Allowance: Designed with a 2mm corrosion allowance to ensure durability and longevity in corrosive environments.

- Seismic Fortification Intensity: Capable of withstanding seismic activity up to 7 degrees, enhancing safety in earthquake-prone areas.

- Working Medium: Compatible with various mediums, including oil, natural gas, water, and ore pulp, making it versatile across different industries.

- Opening Time: The closure can be operated within 60 seconds using less than 200N of force, providing rapid access in critical situations.

- Opening Type: Available in both vertical and horizontal configurations, accommodating diverse installation requirements.

3. Application of EMT Quick Closures

EMT Quick Closures are essential components in high-pressure pipeline engineering, particularly designed for use in pig launchers and receivers. Their applications span various industries and environments, offering numerous benefits:

1. Efficient Access

EMT Quick Closures are engineered for rapid opening and closing, significantly enhancing operational efficiency. Key aspects include:

- Minimized Downtime: By allowing quick access to pipeline systems, these closures help reduce maintenance and inspection time, ensuring that operations can resume swiftly. This is particularly important in critical processes where every minute counts.

- Streamlined Operations: The ease of use means that even a single operator can manage the closure effectively, promoting efficiency and reducing the need for multiple personnel during operations.

2. High-Pressure Environments

These closures are built to withstand demanding operational conditions, with a design pressure range of 1.6 MPa to 30 MPa. This makes them ideal for:

- Oil and Natural Gas Industries: EMT Quick Closures are frequently used in the transportation and processing of these materials, where high pressure and safety are paramount.

- Water Treatment and Distribution: They are also applicable in water supply systems, ensuring secure and reliable connections in high-pressure environments.

- Mineral Processing: In ore pulp applications, the closures provide the necessary durability and resistance to corrosive materials, contributing to efficient processing operations.

3. Safety and Reliability

Safety is a critical concern in high-pressure applications, and EMT Quick Closures are designed with advanced safety features, including:

- Self-Locking Mechanism: This feature ensures that the closure remains securely locked during operation, preventing accidental openings that could lead to hazardous situations.

- Self-Tightening Lip Seal: The unique sealing design minimizes the risk of leaks, providing an additional layer of safety by maintaining a secure seal even under fluctuating pressures.

- Comprehensive Safety Protocols: The closures are equipped with mechanisms that ensure safe operation during pressure changes, protecting both personnel and equipment from potential failures.

4. Versatile Installation

EMT Quick Closures are designed for versatility, accommodating various installation setups:

- Vertical and Horizontal Configurations. The ability to install the closures in both orientations allows for flexibility in pipeline design and layout, making them suitable for a wide range of applications.

- Adaptability to Different Systems. Whether integrated into new systems or retrofitted into existing ones, these closures can be customized to meet specific operational requirements, enhancing their usability across different industries.

5. Seismic Resilience

The design of EMT Quick Closures incorporates considerations for seismic resilience:

- Seismic Fortification. Capable of withstanding seismic activity up to 7 degrees, these closures are suitable for installations in earthquake-prone regions, ensuring that they maintain integrity and performance during seismic events.

- Enhanced Safety in Vulnerable Areas. By providing reliable operation in seismically active zones, EMT Quick Closures help protect critical infrastructure and maintain safety standards in challenging environments.