Description

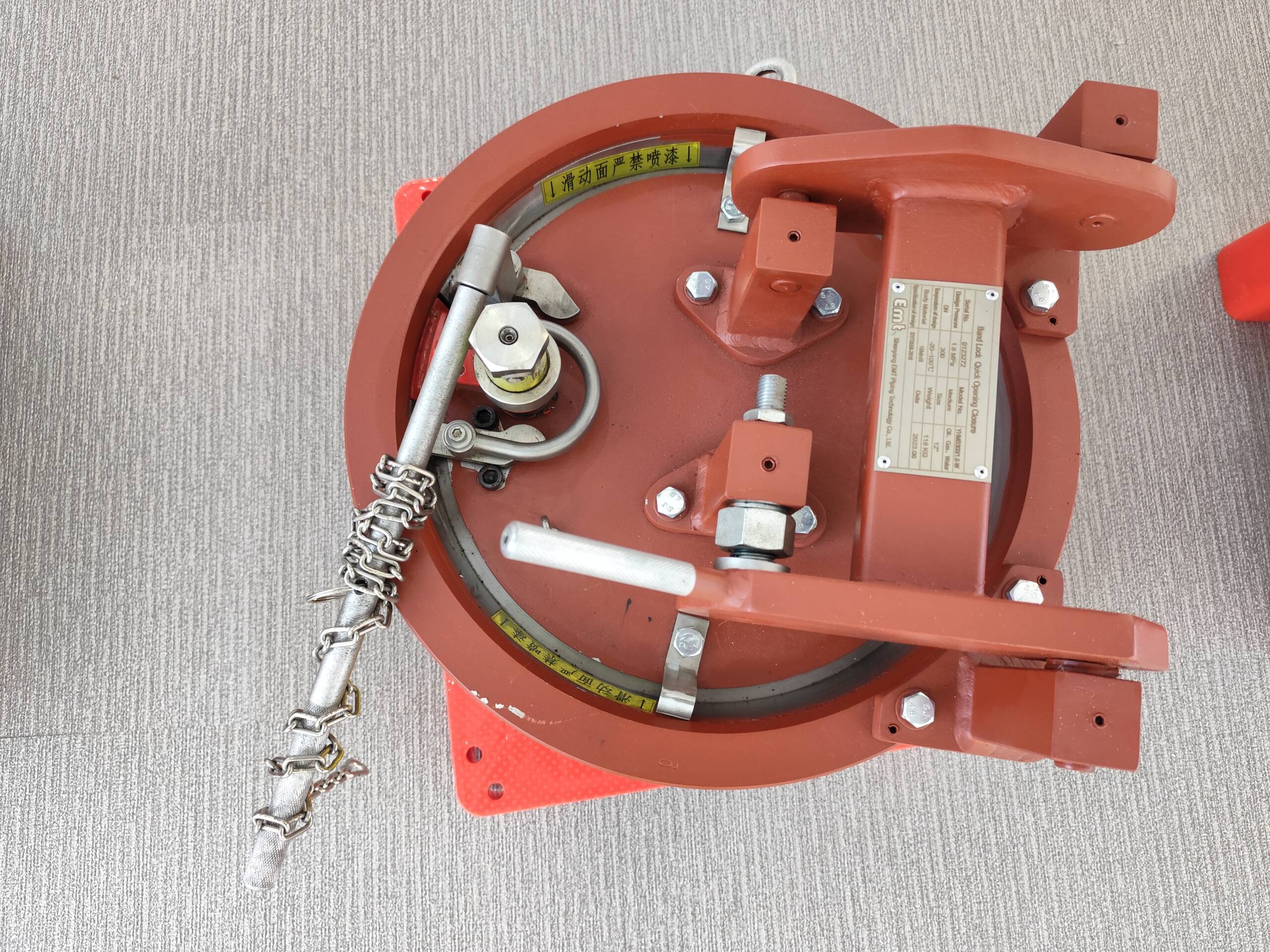

EMT Quick Closures are engineered for high-pressure pipeline engineering applications, providing efficient and reliable access to pig launchers and receivers. These closures are designed with several innovative features that enhance functionality and safety.

1. Key Features of Quick Closures

EMT Quick Closures are designed to provide efficient and secure access to pipeline systems, particularly in high-pressure environments. Below are the expanded details of their key features:

1. Short Operating Time

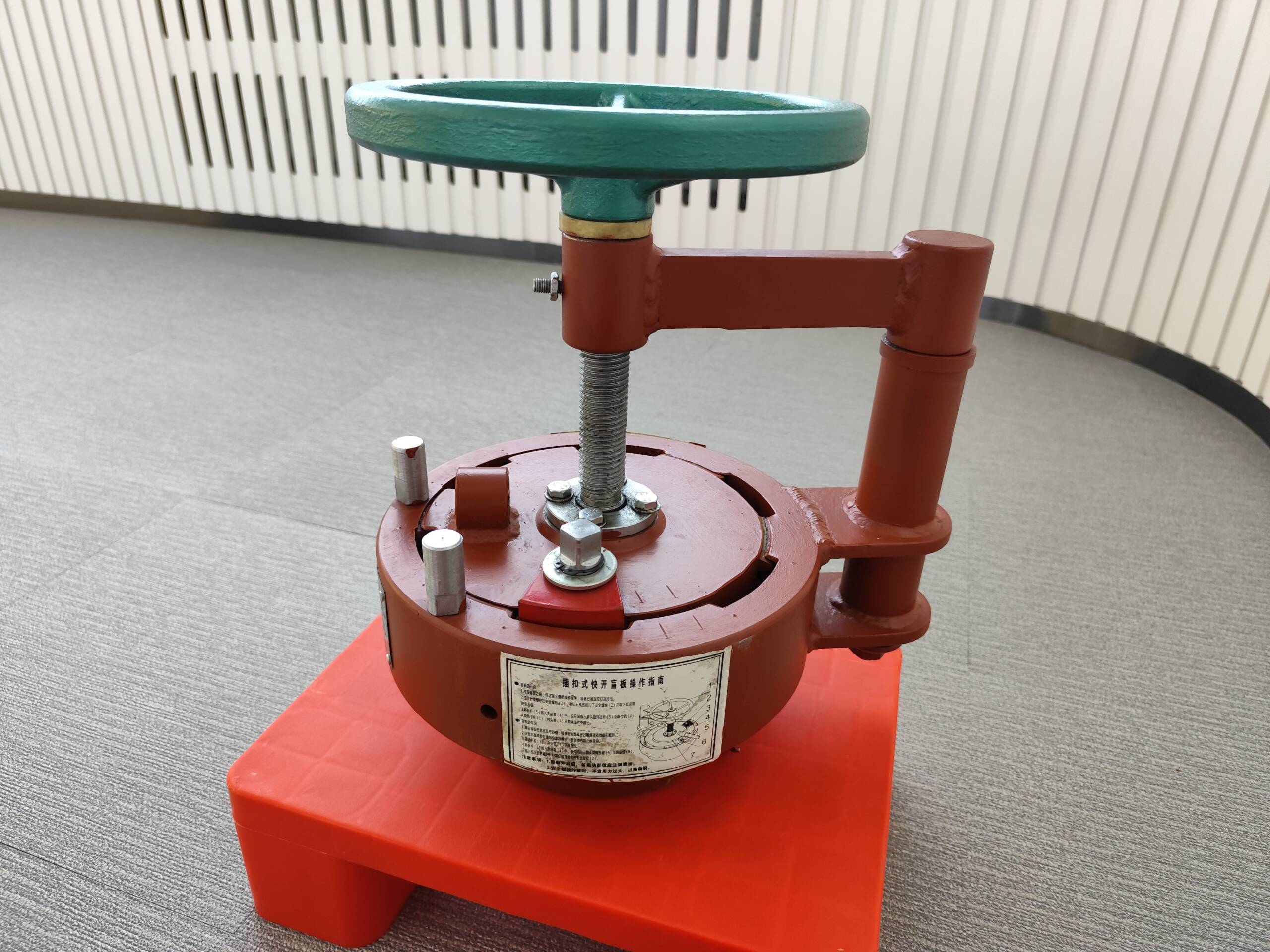

The EMT Quick Closure features a unique locking-ring quick opening mechanism that integrates a scalable locking ring structure. This innovative design significantly reduces the time required for both opening and closing operations, offering several advantages:

- Single-Operator Efficiency: The design allows a single operator to complete the procedure in under one minute, requiring less than 200N of force. This ease of use not only streamlines operations but also enhances productivity, particularly in time-sensitive situations where rapid access is crucial.

- Minimal Downtime: Faster operation translates to reduced downtime, ensuring that maintenance or inspections can be conducted swiftly, thus minimizing disruptions in workflow.

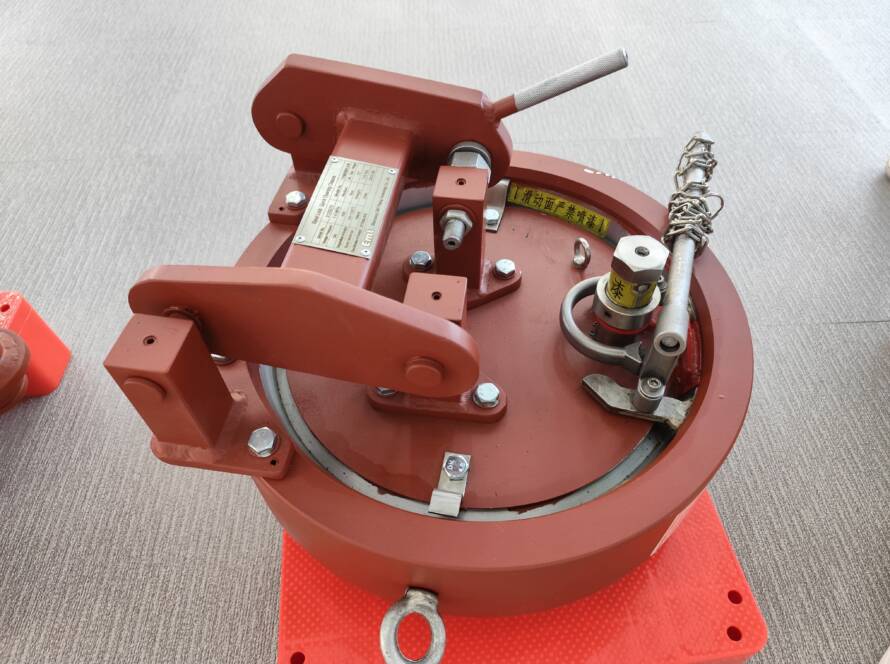

2. Self-Tightening Lip Seal Structure

The closures are equipped with a self-tightening lip seal structure that ensures a robust and reliable seal under varying pressure conditions. Key benefits of this feature include:

- Leak Prevention: The self-tightening mechanism automatically adjusts to maintain a tight seal, significantly reducing the risk of leaks. This is particularly important in high-pressure applications where even minor leaks can lead to safety hazards and operational inefficiencies.

- Durability Under Pressure: The design is engineered to withstand the stresses of high-pressure environments, ensuring that the integrity of the seal is maintained over time, which enhances overall system safety.

3. Safety Lock System

The safety lock system is a critical feature that enhances operational safety by incorporating a self-locking mechanism. This feature includes:

- Pre-Booster Locking. Before boosting pressure within the system, the fast-opening blind and locking structures can be engaged to secure the equipment. This locking function prevents accidental operation, ensuring that the system remains safe and stable until it is confirmed that all safety protocols are in place.

- Post-Unloading Pressure Relief. After the unloading process, the system ensures that the inner pressure is fully relieved before the blind flange cover can be opened. This secondary pressure relief mechanism is essential for avoiding safety hazards that could arise from improper handling, such as sudden pressure release that could lead to accidents or injuries.

2. Additional Safety Features

EMT Quick Closures are not only designed for efficiency but also prioritize safety through various additional features. Here’s a detailed look at these critical components:

1. User-Friendly Design

The design of the EMT Quick Closure mechanism emphasizes intuitive operation, ensuring that it can be easily used by operators with different levels of experience. Then this user-friendly approach includes:

- Clear Instructions and Markings. The mechanism features clearly labeled components and easy-to-follow instructions, allowing operators to quickly understand how to operate the closure without extensive training.

- Ergonomic Handle and Controls. The handles and control mechanisms are designed ergonomically, reducing strain during operation and allowing for smooth, comfortable handling, even in demanding environments.

- Visual Indicators. Many models include visual indicators that show whether the closure is securely locked or in the process of opening or closing. This feature provides immediate feedback to the operator, helping to prevent accidental misoperation.

- Training Support. EMT provides comprehensive training resources and support materials, ensuring that operators can be effectively trained in the use of the closures, further minimizing the risk of human error.

2. Emergency Locking Functionality

The emergency locking functionality is a critical safety feature that enhances the overall security of the closure system. Key aspects include:

- Rapid Response Capability. In the event of an emergency, operators can quickly engage the locking mechanism to secure the closure. This rapid response can prevent potential accidents or spills, protecting both personnel and equipment.

- Fail-Safe Design. The emergency locking system is designed to automatically engage in certain conditions, such as loss of power or pressure anomalies, ensuring that the closure remains secure even if manual intervention is not possible.

- Manual Override Options. For added safety, the system may include manual override options that allow trained personnel to lock or unlock the closure even in power failure situations, ensuring that safety measures remain effective.

3. Robust Construction

The construction of EMT Quick Closures is also a testament to their durability and reliability, designed to withstand the rigors of harsh operational environments. Key features of their robust construction include:

- High-Quality Materials. Made from premium materials such as corrosion-resistant alloys or reinforced polymers, EMT Quick Closures are built to resist wear and tear, ensuring longevity and reducing maintenance needs.

- Pressure Resistance. Engineered to handle high pressures, these closures maintain structural integrity under extreme conditions, protecting against failures that could lead to leaks or spills.

- Environmental Resilience. The closures are designed to endure various environmental factors, including temperature fluctuations, humidity, and exposure to chemicals, then making them suitable for a wide range of applications in different industries.

- Quality Assurance Standards. EMT Quick Closures undergo rigorous testing and quality assurance processes to ensure they meet industry standards for safety and performance, also providing operators with confidence in their reliability.

3. Specifications of Quick Closures

- Design Pressure. The closures are rated for pressures ranging from 1.6 MPa to 30 MPa, making them suitable for demanding applications.

- Corrosion Allowance. A corrosion allowance of 2mm is included, ensuring durability and longevity in various working environments.

- Seismic Fortification Intensity. Designed to withstand seismic activity up to 7 degrees, enhancing safety in seismic-prone areas.

- Working Medium. Suitable for a range of media, including oil, natural gas, water, and ore pulp, providing versatility across different industries.

- Opening Time. The closure can be opened within 60 seconds with less than 200N of force, allowing for rapid access in critical situations.

- Opening Type. Available in both vertical and horizontal configurations, accommodating various installation requirements.