Description

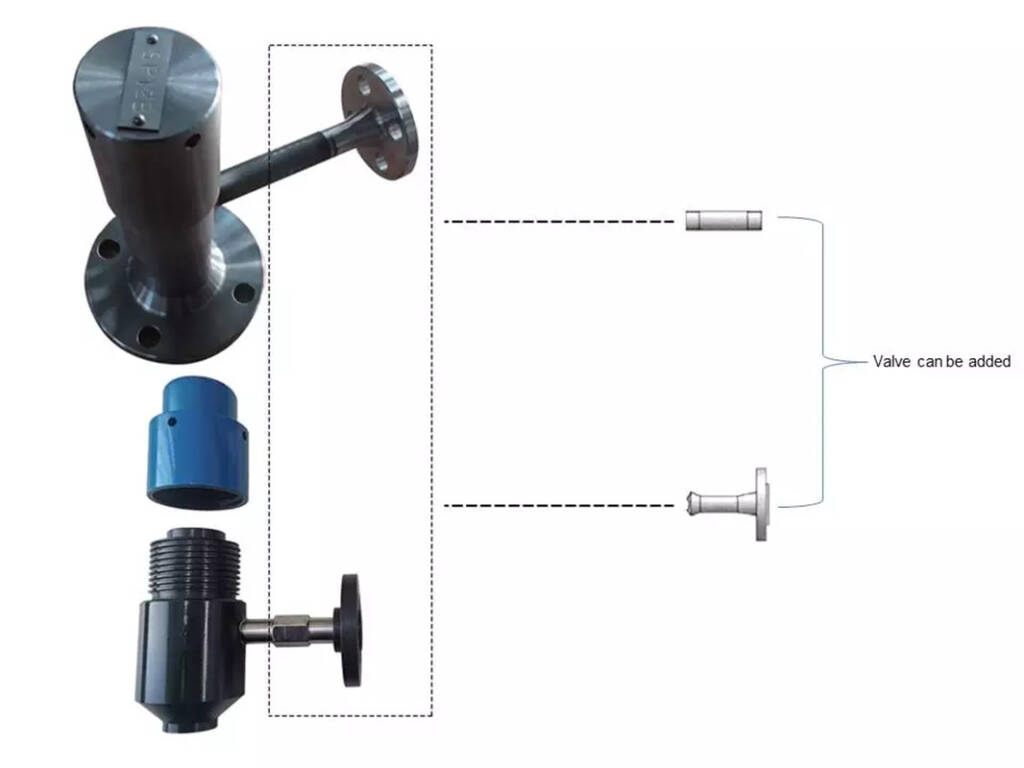

EMT Quill Chemical Injection, designed and manufactured by EMT Pigging, is a specialized device used primarily in the oil and gas industry, as well as in other sectors like mining and construction. This system is integral to maintaining pipeline integrity through the controlled injection of chemicals directly into the pipeline stream. These chemicals help in preventing corrosion, scaling, and fouling that can severely impact pipeline operations.

1. Product Specifications:

- Sealing Material: Fluororubber

- Working Temperature: -20 to 200°C

- Working Pressure Options: 150LB, 300LB, 600LB, 900LB, 1500LB

- Solid Plug Assembly Material: 316L Stainless Steel

- Injection Tube Material: 316L Stainless Steel

- NPT Nozzle Material: 316L Stainless Steel

- Flange Material: ASTM A105N

- Certification: ISO 9001

- Warranty: 1.5 years

2. Parameter:

- Usage: The Chemical Injection Quill is designed for periodic injection of chemical inhibitors into pipelines to control or minimize corrosion efficiently. This system allows for the injection of chemicals under operating pressure safely and reliably.

- Mounting Types:

- 2″ Flange

- 2″ Flareweld Access Fitting

- 1″ Nipple to NPT Ball Valve

- Pressure Rating: Up to 6000 PSI or as per Flange Size

- Temperature Range: -20 °C to 150 °C

Name |

Chemical Injector Quill |

|

| Material | Stainless Steel 304, Stainless Steel 316, DSS F51, Carbon Steel A105N, and also Inconel 625 | |

| Operating Temperature | -20±120 | |

| Feature | Firstly, easy Operating | |

| Secondly, high Accuracy Long Life | ||

| At last, high Efficiency, Low cost | ||

| Payment | TT/LC | |

| Advantage | Firstly, they are lightweight and flexible. | |

| Secondly, excellent Injection efficiency. | ||

| At last, accurate location tracking. |

| Model | ||||||||||||||||||||||||||||

SI |

Chemical Injector Quill |

|||||||||||||||||||||||||||

| -Code | Plug | |||||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | |||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | |||||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | |||||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | |||||||||||||||||||||

| Code |

Injection Nut |

|||||||||||||||||||||||||||

| Nxx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 3 | i.e. DSS | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 4 | i.e. INCONEL | |||||||||||||||||||||||

| – Code | Injection Tube | |||||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | ||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | i.e. No Request | The most effective position for injection is generally at the center of the pipe | ||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 1 | i.e. Open | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 2 | i.e. Quill | |||||||||||||||||||||||

| 3 | i.e. DSS | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | i.e. INCONEL | |||||||||||||||||||||||||||

| – Code | Nipple and Valve(or end Flange)of Tee | |||||||||||||||||||||||||||

| Txx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | i.e. 1/4″Nipple | a | i.e. 1/4″Nipple and Valve | 1 | i.e. 316SS | |||||||||||||||||||||||

| 2 | i.e. 1/2″Nipple | b | i.e. 1/2″Nipple and Valve | 2 | i.e. 316LSS | |||||||||||||||||||||||

| 3 | i.e. 3/4″Nipple | c | i.e. 3/4″Nipple and Valve | 3 | i.e. D SS | |||||||||||||||||||||||

| 4 | i.e. 1″Nipple | d | i.e. 1″Nipple and Valve | 4 | i.e. INCONEL | |||||||||||||||||||||||

| 5 | i.e. 1/4″Flange | e | i.e. 1/4″Nipple end Flange | |||||||||||||||||||||||||

| 6 | i.e. 1/2″Flange | f | i.e. 1/2″Nipple end Flange | |||||||||||||||||||||||||

| 7 | i.e. 3/4″Flange | g | i.e. 3/4″Nipple end Flange | |||||||||||||||||||||||||

| 8 | i.e. 1″Flange | h | i.e. 1″Nipple end Flange | |||||||||||||||||||||||||

3. Applicable Industries:

- Building Material Shops

- Construction Works

- Energy & Mining

- Pipeline Pigging

- Oil & Gas Pipeline