Description

1. Introduction

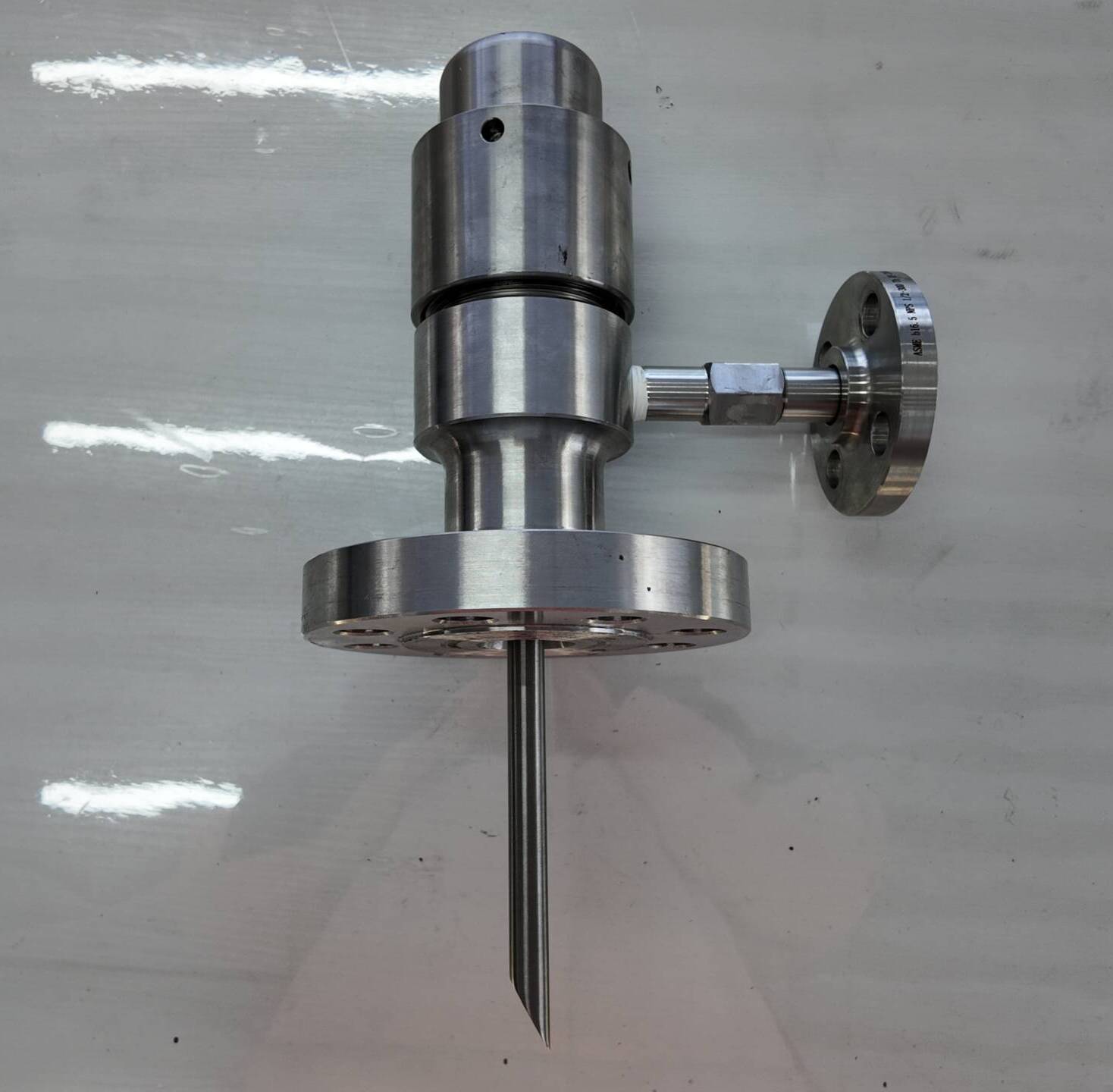

The Quill Chemical Injection EMT-CI is a state-of-the-art solution designed for precisely and efficiently injecting chemicals into pipelines and other systems. This device is crucial in various industrial applications, including oil and natural gas extraction, chemical processing, and heavy manufacturing. With its robust design and customizable features, the Quill Chemical Injection EMT-CI can handle a wide range of chemical types under different operational conditions.

Name |

Quill Chemical Injection EMT-CI |

|

| Material | Stainless Steel 304, Stainless Steel 316, DSS F51, Carbon Steel A105N, and also Inconel 625 | |

| Operating Temperature | -20±120 | |

| Feature | Firstly, easy Operating | |

| Secondly, high Accuracy Long Life | ||

| At last, high Efficiency, Low cost | ||

| Payment | TT/LC | |

| Advantage | Firstly, they are lightweight and flexible. | |

| Secondly, excellent Injection efficiency. | ||

| At last, accurate location tracking. |

2. Key Features and Customization Options

Material Customization:

EMT offers the Quill Chemical Injection EMT-CI in a variety of materials to suit specific industry needs and chemical characteristics. Available materials include:

- Carbon Steel: For standard applications requiring durability.

- Dual-Phase Steel: Offers enhanced strength and corrosion resistance.

- Stainless Steel: Best for high corrosion resistance in harsh chemical environments.

Interface Customization:

Depending on the pipeline or vessel connection requirements, EMT can customize the interface of the Quill Chemical Injector to match any system seamlessly. Options include:

- Flanged Connections: Ideal for larger pipes and high-pressure applications.

- Welding Connections: Provides a permanent and robust connection.

- 2-Inch Threaded Joints: Suitable for smaller or lower-pressure setups.

3. Applications of Quill Chemical Injection EMT-CI

- Corrosion Inhibitors: It injects chemicals that prevent rust in pipelines and wells, ensuring long-term durability.

- Scale Inhibitors: It helps in preventing the formation of mineral deposits that can clog up systems.

- Biocides: These chemicals are crucial for stopping microbial growth that can corrode and block pipelines.

- Demulsifiers: It efficiently separates oil from water in production fluids, enhancing the quality and ease of processing.

Chemical Processing

- Oxidants: The injector is used to add oxidizing agents that react with and degrade contaminants and impurities.

- Flocculants: It introduces agents that help in clumping together fine particles into larger aggregates, simplifying their removal from liquids.

- Precise Dosing: Delivers exact chemical quantities needed for reactions, ensuring process reliability and consistency.

Cooling Systems

- Biocide Injection: Injects chemicals to prevent biofilm formation and microbial-induced corrosion inside cooling towers and systems.

- Scale Prevention: Regularly adds scale inhibitors to maintain the efficiency and operational integrity of cooling systems.

- Water Treatment: Ensures water used in cooling processes is treated to prevent fouling and increase system longevity.

Heavy Manufacturing

- Continuous Chemical Delivery: Provides a steady stream of necessary chemicals into manufacturing processes without interruptions.

- Process Optimization: Enhances production efficiency by maintaining optimal chemical levels in the system, reducing waste and increasing output quality.

- Equipment Protection: Injects protective chemicals that help extend the life of manufacturing equipment by preventing corrosive damage.

4. Advanced Features of Quill Chemical Injection EMT-CI

Safety and Operational Efficiency:

- Pressure Start Function: Allows the system to initiate only when certain pressure conditions are met, enhancing safety and resource efficiency.

- Pressure Stop Function: Automatically ceases operation when the system reaches a preset pressure level.

Technical Design:

- Compact and Lightweight: Ensures easy integration into existing systems without requiring extensive modifications.

- High Corrosion Resistance: The use of imported stainless steel and other high-quality materials extends the life of the injector in corrosive environments.

- Explosion-Proof: The gas-driven mechanism eliminates the risk of sparks, making it safe for use in volatile environments.