Description

Mechanical Engineering / Industrial Equipment

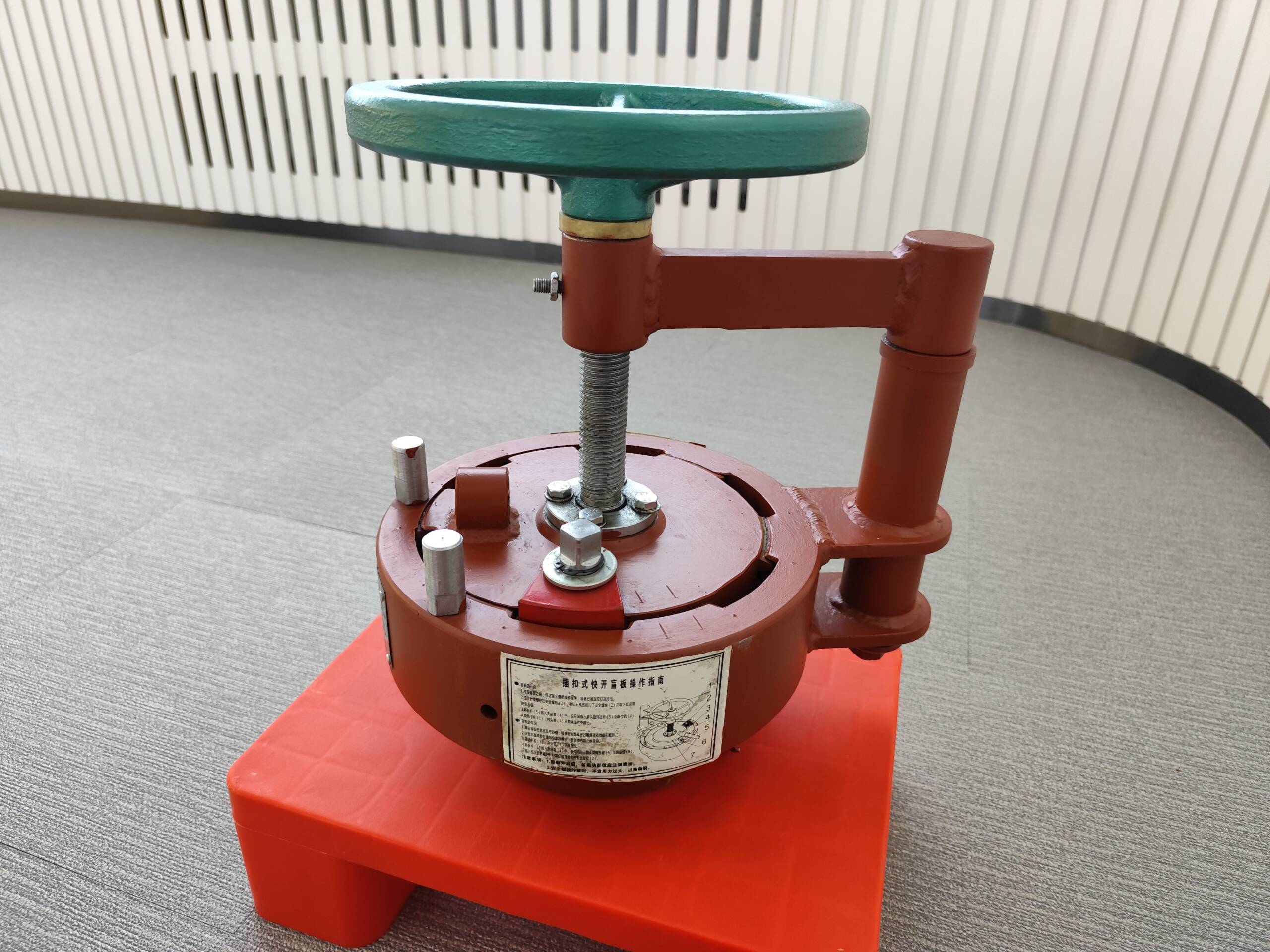

A Rapid Opening Closure (ROC) is a specialized mechanical device used to secure and quickly access pressure vessels or pipelines, such as:

- Pig traps in oil and gas pipelines

- Pressure vessels

- Filters or separators

Key Features:

- Quick access without tools

- Pressure-sealed for safety

- Often uses clamps, toggles, or bayonet mechanisms

- Can be operated manually or hydraulically

Benefits:

- Reduced downtime for maintenance or inspections

- Improved safety through secure locking mechanisms

- Efficiency in high-pressure applications

What Are Rapid Opening Closures and Why Are They Essential?

In the oil, gas, and process industries, safety, efficiency, and reliability are top priorities. One crucial component that helps achieve these goals is the pipeline closure. Though relatively compact, this device plays a major role in enabling safe and efficient maintenance of pressurized pipelines.

What Is a Rapid Opening Closure?

A Rapid Opening Closure (ROC), also known as a quick opening closure (QOC), is a mechanical device installed on a pipeline or pressure vessel to allow fast and secure access to the interior. These closures are commonly found at the ends of pig launchers and receivers, filters, separators, and pressure vessels.

Unlike traditional methods that require cutting, welding, or bolting, pipeline closures are designed to open and close quickly without compromising safety. This makes them an ideal solution for industries that demand regular access for inspection, cleaning (pigging), or maintenance.

Key Benefits of Pipeline Closures

Fast Access

Pipeline closures significantly reduce downtime by allowing personnel to open and close the vessel or pipeline quickly. This is especially valuable in high-pressure systems where time is critical.

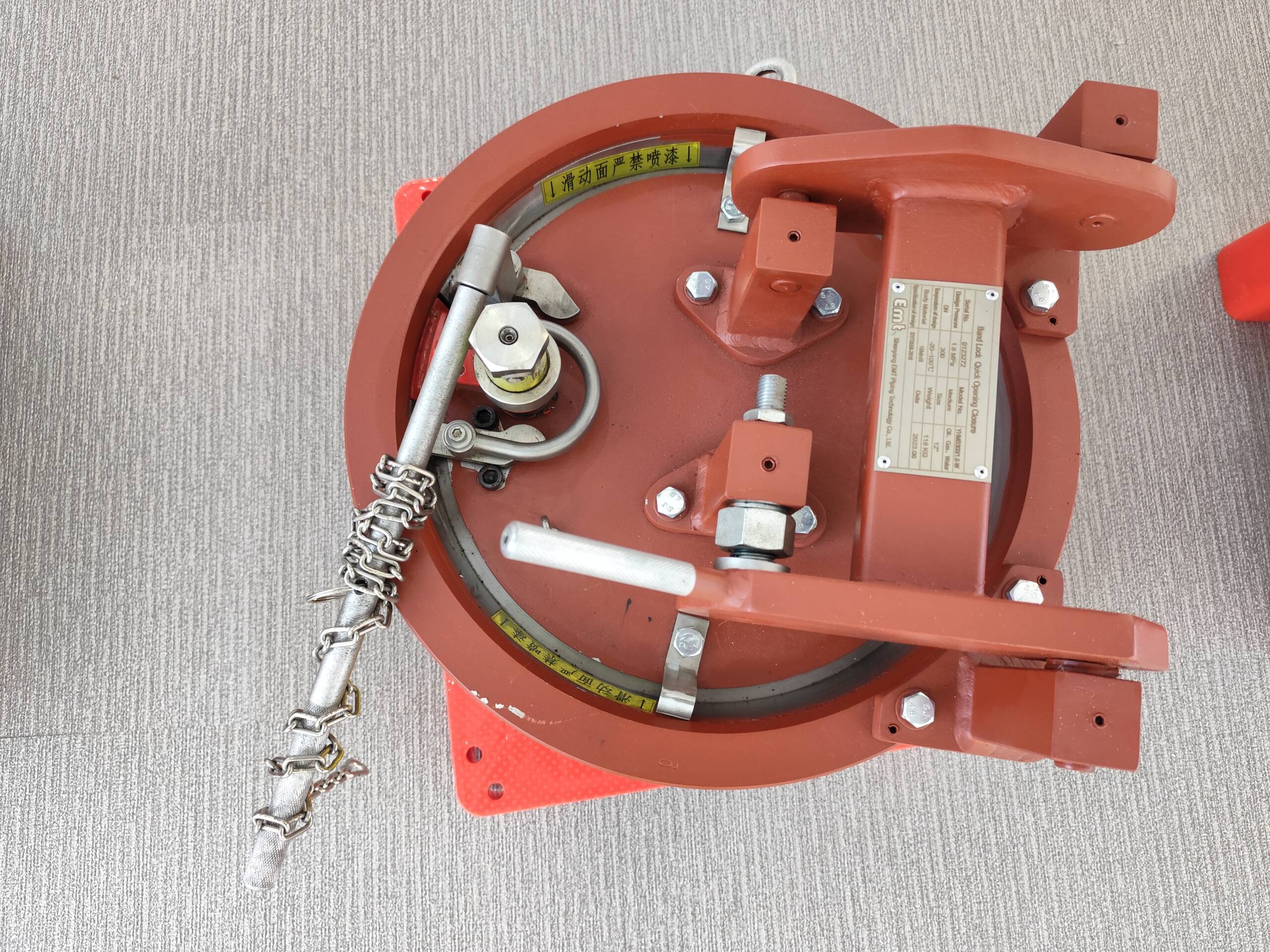

Enhanced Safety

High-quality closures are built to withstand high pressure and prevent accidental opening under load. Many designs include safety interlocks and pressure warning systems to ensure safe operation.

Cost-Effective Maintenance

By eliminating the need for cutting or welding, pipeline closures reduce labor costs and equipment downtime. Their reliable sealing also minimizes the risk of leaks and product loss.

Versatile Applications

Pipeline closures are used across various industries, including oil & gas, chemical processing, water treatment, and food processing. Their ability to handle different pressure ratings and materials makes them suitable for a wide range of applications.

Common Types of Closures

There are several types of pipeline closures, each suited to different operational needs:

Clamp-Type Closures: Use a clamping mechanism to secure the door. Fast and easy to operate.

Bayonet-Type Closures: Rely on a rotating locking mechanism. Often used in high-pressure systems.

Threaded Closures: Screw-on design ideal for small diameters and low-frequency access.

Hinged Closures: Feature a hinged door that swings open, often used for horizontal vessels.

Choosing the Right Closure

When selecting a pipeline closure, consider the following factors:

Operating pressure and temperature

Frequency of access

Pipeline diameter and orientation

Industry-specific standards (e.g., ASME, API)

Partnering with a reputable manufacturer ensures compliance with safety regulations and long-term reliability.

Final Thoughts

Pipeline closures may seem like a small part of a complex system, but their impact on safety, efficiency, and maintenance is substantial. Whether you’re operating a pigging system or managing a high-pressure vessel, investing in the right closure can save time, reduce costs, and improve overall performance.

Looking for high-quality pipeline closures? Contact our team today to find the right solution for your operations.