Description

Advantages

Our EMT Retriever Tool has the capability to retrieve corrosion coupons without shutting down the pipeline offers several benefits:

Continuous Operation:

The pipeline can continue to operate normally without interruptions, maintaining productivity and avoiding downtime.

Cost Efficiency:

By eliminating the need for shutdowns, there are significant savings on operational costs and resources that would otherwise be spent on system closures and restarts.

Safety and Convenience:

The process is safer and more convenient as there is no need to depressurize or drain the system, reducing the risks associated with handling pressurized or hazardous contents.

Immediate Access and Monitoring:

Immediate retrieval allows for quick and timely access to corrosion data, facilitating more responsive maintenance decisions and monitoring.

Minimal Impact on System Integrity:

Since the system remains operational, the integrity and pressure of the pipeline are maintained, reducing the risk of system issues related to pressure changes.

Parameters

| Letter | Description | Maximum Pipeline Size | ||

| 12″ | 24″ | 36″ | ||

| A | Retriever (mm) | 710 | 1000 | 1300 |

| B | Retriever and Service Valve (mm) | 985 | 1275 | 1575 |

| C | Stroke Available (mm) | 600 | 881 | 1184 |

| Weights (kg) | 25.4 | 27.6 | 30 | |

Key Functions of the Retriever Tool

Corrosion Coupon Retrieval

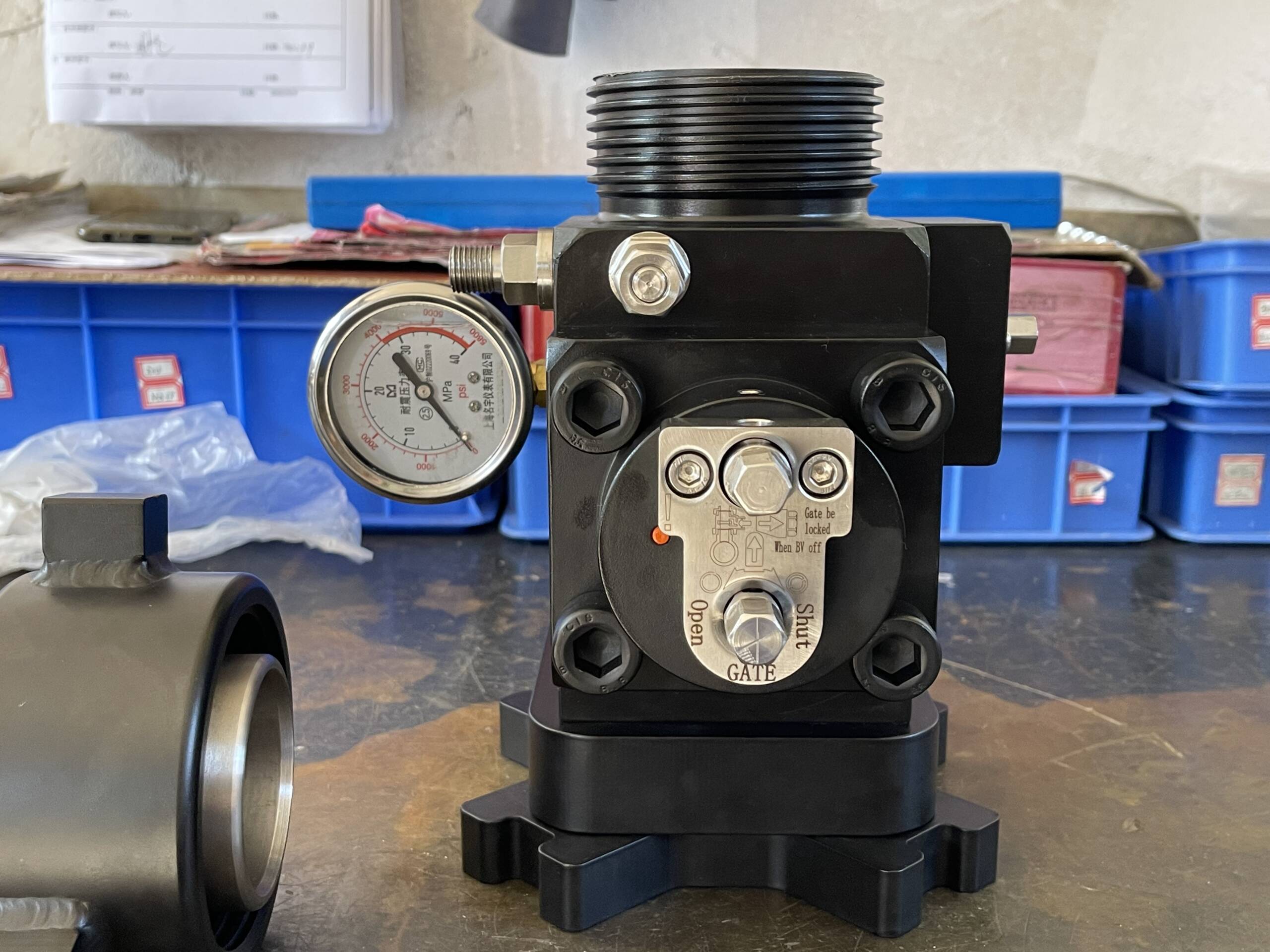

The Retriever Tool significantly enhances preventive maintenance strategies within industrial settings. Corrosion Coupon Retrieval serves a critical function. Operators use corrosion coupons to gauge the rate of corrosion within pipelines or vessels. By retrieving these coupons, they can evaluate material loss and implement necessary preventive measures. The process is straightforward: the tool attaches to the coupon holder inside the pipeline. This allows operators to safely remove the coupon for analysis without halting system operations.

Chemical Injection Quill Retrieval

Moving on to Chemical Injection Quill Retrieval, this function is equally essential. Chemical injection quills inject corrosion inhibitors, scale inhibitors, and other chemicals into a pipeline’s flowing stream at high pressure. Retrieving these quills facilitates maintenance, inspection, and replacement activities without needing to stop the system. The tool operates similarly to the corrosion coupon retrieval, securely grasping the quill and withdrawing it from the pressurized environment without disrupting pipeline operations.

Corrosion Probe Retrieval

Lastly, the Corrosion Probe Retrieval aspect of the tool is indispensable for accurate system monitoring. Corrosion probes deliver real-time data on corrosion rates and system characteristics. Retrieving these probes is vital for recalibration, maintenance, or replacement, ensuring precise monitoring continues. The tool connects to and removes various types of corrosion probes, supporting ongoing maintenance and monitoring efforts without requiring a system shutdown. This capability ensures continuous operation and safety, underlining the tool’s importance in maintaining system health and efficiency.

Advantages of Using This Retriever Tool

Operational Efficiency: Enables continuous operation of the system by allowing maintenance and monitoring tasks to be performed without shutdowns.

Safety: Designed to operate under pressure, reducing the risk associated with depressurizing and re-pressurizing systems, which can be hazardous and time-consuming.

Cost-Effectiveness: Reduces operational costs by minimizing downtime and maintaining productivity during essential maintenance tasks.

Versatility: The ability to handle multiple types of retrievals with one tool simplifies operations and reduces the need for multiple specialized tools.

Applications

This Retriever Tool is particularly useful in industries where pipeline integrity and fluid quality are critical, such as in oil and gas production, chemical manufacturing, and utilities. Its robust design and versatile applications make it an invaluable asset for maintaining system efficiency, safety, and reliability.

By incorporating this tool, facilities can enhance their preventive maintenance strategies. It ensures continuous monitoring of corrosive activities. Additionally, it effectively manages chemical dosing. All these factors contribute to prolonged system life and improved operational safety.

Main Features of Retriever Tool

The Retriever Tool offers several significant advantages that make it a valuable asset in maintaining and monitoring pipeline systems. Its design and functionality cater to the needs of operators focusing on efficiency, safety, and ease of use. Here’s an elaboration on each of the highlighted advantages:

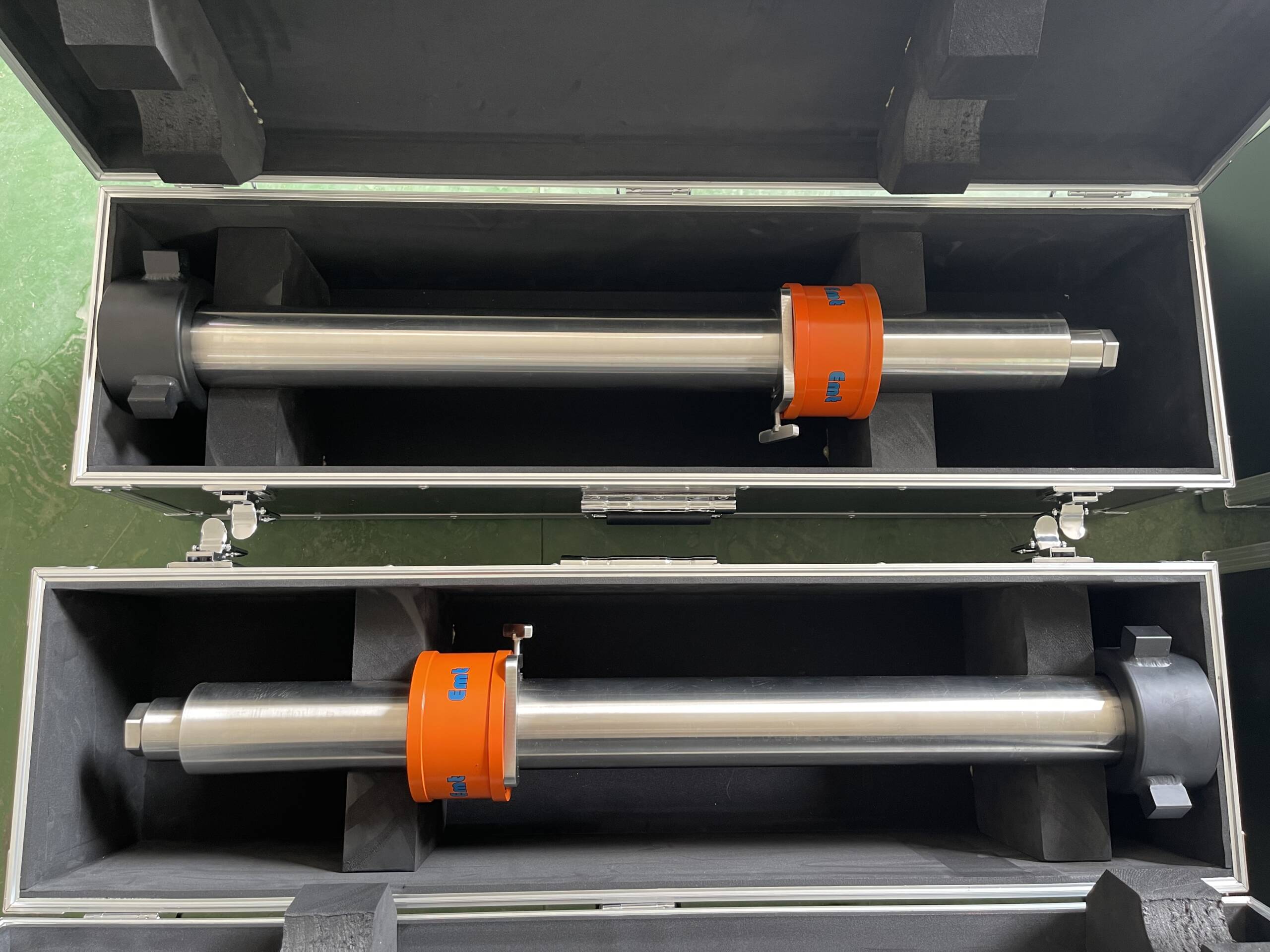

Portability: The tool’s lightweight and compact design make it highly portable, allowing operators to easily transport it between different sites and sections of a pipeline. This portability is crucial in large facilities or expansive pipeline networks where mobility enhances operational efficiency. Operators can quickly respond to maintenance needs anywhere within the system without the burden of heavy or cumbersome equipment.

Ease of Use: The Retriever Tool is designed with user-friendliness in mind. It features intuitive controls and mechanisms that simplify its operation. This ease of use reduces the training time required for operators and minimizes the likelihood of operational errors. Even in complex maintenance tasks, such as retrieving corrosion probes or injection quills, the straightforward operation of the tool ensures that tasks are completed efficiently and accurately.

Single-Operator Requirement: One of the most significant advantages of the Retriever Tool is that it requires only one operator to manage the retrieval process. This feature is particularly beneficial in terms of labor costs and operational logistics. By enabling a single operator to perform what would typically be a two-person job, the tool not only reduces the workforce requirement but also enhances the flexibility of maintenance scheduling and deployment. This capability allows for more frequent inspections and maintenance activities, as it does not heavily rely on large teams, thus keeping the system in optimal condition with minimal human resources.